| Subtopic | Posts | Updated | ||

| EB1 Noises | 1 | 02/15 03:18am | ||

| Of Honda Interest | 1 | 02/12 09:27pm | ||

| For sale- 1976 Honda Civic-one owner | 1 | 02/09 02:55pm | ||

| Rear brake options for 4x100 | 1 | 02/07 06:18am |

| |

I have been given a few motors.

I Have a block for a EB2 with new pistons and new rings, and the block has been howned, The head looks just OK.

I have a complete EB3 Runs good but burns alittle oil, But leaks like bad.

Can these engines been interchanged like, like useing the Eb3 crank and rods, EB2 block and pistons, with the EB3 head?

| |

The pistons must match the head. Eb2 heads are not that bad, once you work them a little.

| |

I heard that the valves are larger on the EB3 head. Would that not make it a better joice?

| |

I depends on the use, PJ uses a EB2 head on his race car,1300 cam header ect. The eb2 head has smaller ports and the valves are not shrouded by the cylinders as much. With some smart port work the eb2 head will flow more air than the stock eb3. For a daily driver a worked eb2 head is the better choice, more grunt down low.

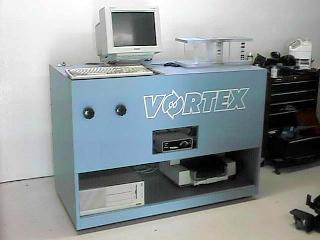

PS I'm not pulling this stuff out of my butt, here is a picture of my flowbench. With the limited time I have spent, the eb2 head looks to be a great head.

| |

Thanks for the info.

So what you are saying is that I should use most of the Eb2 parts? I have only rebuilt a few engines, my 15 year old and I are taking on the project together, we have alot to learn together to put this together correctly. Any advice would be greatly appreciated.

I keep here about 1300 parts that are good to use. What parts exactly should I try and get from my local wrecker, to add into my motor? What motor are these from?

| |

I forgot to mention that this will be my son's first car when turns 16. He keeps asking me how we can get more power out of the engine, but are funds are limited on the rebuild. My be some simple combinations of different motors can give us the best results?

| |

The problem with engine mods is that they are dependent on one another. You should start with a sound engine (its sounds like the eb2 is) was the block over bored? If not make sure the taper is within specs!!! Then if the buget allows get a header and a free flow exhaust. The stock carb can be reworked to give reasonable performance. Jackson Racing used to rework the stock carbs and may do it again or you could get a Weber conversion.

The head must be within factory specs.. No loose worn guides,spring hights set, no warpage. Then a good valve job and a minor blending of the short turn and the bowl will give good results.

You could pick up a 1300 crank and rods to put in there.

No engine is going to last or give much power if its not sealed, I have seen people "re ring" an engine bolt on a used head and complain in 10,000 miles or less cause its worse than before. A quality machinist is you best investment.

Were do you live?

| |

Hey Don,

Where are you located?

| |

I live in Oregon, big bear country! ![]() Na if a bear came around here it would probably get hit by a Semi.

Na if a bear came around here it would probably get hit by a Semi.

| |

What year do I get a 1300 crank from? What about the cam? Does the 1300 crank have a different stroke or is it just stronger?

The EB2 block has been howned only, done by a shop. I don't have the Carb for the EB2. Will the intake man. and Carb fit from the EB3? The Eb3 Carb was rebuilt a few months ago.

| |

The EB3(1237cc) intake and carb will fit EB2(1237cc).If your in Canada look for an EN1(1335cc) 80-83 Civic 3dr.If your in the US you want a EJ1 (1335cc) cvcc 80-83 Civic.![]()

| |

Just cause a machine shop honed the block does not mean that the taper is within specs. The machine work is the foundation that you build upon.

A block that has taper in the cylinders will NOT get better after its honed. Check this or have it checked so you know your starting on a solid base.

An aftermarket camshaft or stoker 1300 EJ/EN crank (yes its longer) will do no good if you cant keep the pressure from blowing down in the crankcase.

This is the kind of thing where a few minutes can save you hours later.

Also the piston rings have a certain order and have a top and bottom.

Get a factory manual and or a "how to rebuild your honda engine" book.

| |

I agree with Don... the machine shop is either your best friend, or your worst enemy.

Don,

Do you guys have a torque plate to bore these Civic engines with?

| |

No, but before I bore my new engine I will. BJH will make them. Two are needed one for the block and one for the head to simulate the bolt stress, it makes a difference in the seat run out. If your a real stickler you can purchase a pump and a heater to pump 180 degree water through the head and torque plate while the valve job or the block while the bore is being done.

Tom, none of this is needed for a good street engine but they dont hurt!

| |

Don

I went with the eb2 head and block. I've just got them back from a very good machine shop in the area. Every looks great and in spec.

I have been doing some reading on line and there seems to be alot of talk about what is better in the bottom and pistons.

Should I stay with the stock Crank or go with the 1300 crank and rods?

What about the piston, should I stay with the standard eb2 pistons or change to eb3 or gold wing pistons?

If I go with the 1300 crank and rods and stock piston will my compresion ratio be to high?

| |

I think the best bet would be 1300 crank and rods. The compression will be raised slightly with the longer 1300 stroke.

Dont use anything but eb2 pistons with an eb2 head

for daily use.

| |

Great Stuff

My next adventure will to be able to find a good crank with rods.

Can I pull the crank and rods out the bottom of an EN still in the car or is there something blocking the oil pan?

Is there any other parts of the EN that would help my rebuild.

| |

You can't pull the pistons out the bottom of the block, they can only come out the top.

You also want the EN sump and oil pump.

Using an EN1 bottom end with an EB2 head will give you a very high CR (probably around 11 or 12:1) unless you use deeply dished pistons.

| |

Stock USA 1238 CC EB2 max stock compression 8.3 (per factory manual). 7.7 min

So if we go from a 1200 crank and rods to a 1300 set (2.99 to 3.23 inch stroke)

brings the max compression to 8.9 or 8.3 min (per mathematics) if you over bored the engine it would be higher but only slightly about.3 for a .040" over bore. Be sure to include any head milling into your plan 9.5 is still plenty safe for good pump gas. Felpro aftermarket head gaskets are thicker than the Honda ones, this will lower you compression ratio. So Tom an engine is not just a few parts thrown together, you must know and calculate all items in an engine to get to the desired result.

If you use the eb3 pistons or Goldwing pistions the compression could be way up there like Adrian said.

So use EB2 dished pistons and you will be ok.

PS I have a spreadsheet made up that will calculate things like compression ratio or piston velocity... etc. Free to who ever wants it.

You will have to fill in your own spec's as its now loaded with the 400 CI 14.1 Ford engine I built last.

| |

Oh' since you want an EN, I guess your not in the USA. So maybe the compression ratio is not the same as a USA model. PS the above spec's are in inches,not MM. sorry I grew up working on American stuff.

| |

Don,

I'd really like that spread sheet you refered to. Please e-mail to rogeredens@yahoo.com.

Roger

| |

Is the only difference between the EB2 head and the EB3 head the valve size? Because I bought an "eb3" head from a guy online. When it arrived it looked great, and it's been sitting in my room waiting for it's turn to be massaged.

Well, I just bought a pair of digital calipers so I figured I'd measure everything. Well, it's got a 34mm intake valve and a 30mm exhaust, but the valve seats are cut out to 36.5+mm and 33+mm. Could it be an EB3 that's just got EB2 valves in it? If it is an EB2 is there any reason why I can't just put EB3 valves in it, and have an EB3?

| |

EB2 and EB3 heads are totally different. EB3 has bigger (deeper) combustion chambers, bigger ports and bigger valves.

| |

An easy way to tell the difference is EB2 heads are marked with an S (exhaust side rear) EB3 heads are marked with an H ![]()

| |

Justin

I just mesured my EB2 The intake measured 29mm and the Exhaust 24.5. This is quit different from your numbers.

| |

Justin,

Did you measure the port or the valve? The exhaust valve (I just took it out) has a 30mm head, but the port is about 25mm. And, it has an S on it, so it's an EB2. I guess I'll just have to hunt down an EB3 again. The junk yard had an EB3 head out in the yard. I'll probably pick it up.

| |

The valve

| |

Hey Don, I'd like that speadsheet also. Since my recent job change my project has stalled but I can still do research etc.! I haven't sent the head to the machine shop yet & it is a virgin. I can measure the chambers before it is milled. Thanks Dennis

dennissingley@msn.com

| |

The spread sheets are sent, its in a Microsoft Works format, If it does not open let me know and I can change the format to Excel, or Lotus depending on the spread sheet program you have.

| |

Sorry Tom,

I read Justin on your message and it messed me all up. I really can't say why they are different numbers. The valves don't really look aftermarket, they're big and bulky. Any other thoughts?

| |

Don, could I get a copy of your spreed sheet please.

stobrien@shaw.ca

| |

Can any one tell me the difference and how much between the 1200 rods and the 1300 rods. Can I use a 1300 crank with the 1200 Rods.

| |

3mm. 1200 rods could be used with some custom pistons.

| |

is that 3mm shorter or longer? The reason I ask is that I got some 1300 rods but when trying to press out the shaft I bent the rod. Is there any easy way to remove the pistons from the rods.

| |

Anybody that cares, Manley will custom make Titanium valves for $100 ea. and stainless valves for $21-$28 ea. (U.S.).

| |

The 1200 rods are 3mm longer than the 1300 rods. To use them you'll have to either cut 3mm from the top of an exsisting piston, or have some customs made and have them move the pin up a bit. Honda makes a special jig for taking pistons off the rods. It can be done without this tool, but I wouldn't recommend it.

| |

Hey Don, I have had some e-mail problems & I didn't get the spread sheet. I sure would appreciate it if you could send it again. Thanks, Dennis

dennissingley@msn.com

| |

Don, I too would like the data as I'm going to be doing this work in the future

tedd@oslc.org

| |

Might as well make it a list. Thanks Don.

ReTodd1200@springmail.com

| |

The spread sheet is a poorman's spreadsheet similar (well about 1/8) to a very expensive DOS program called Engine Expert ($1700)

There is a very good home study engine design course that teaches how to use EE and Dynomation together and is around $150 from Allan Lockheed that I would recomend even if you never use the real programs. You will learn more in 16 hrs of audio that you would ever learn in a life time of tinkering. All for less than the cost of one mis-picked camshaft.

Also I do have the real programs and can do the required inputs and send the required printouts if you guys learn how to used the data. The cost will be very reasonable, around $30 for the basic data. After all I do have to make some of the capital outlay back ![]()

The printouts or the knockoff spread sheet will not be able to be used to its full potental with out the engine design course. This stuff is not for beginners and it has a ton of math, but I think quite a few people would be able to see "the light" after finishing the program.

| |

I think everyone that asked got a copy, if I missed someone let me know.

| |

I got mine, thanks Don!

| |

hi don,

just interested in what sort of figures u get out of a decent head and which would be the best type to start with race application

| |

I have not spent allot of time on the eb heads at all. I pulled an eb2 head about a year ago and compared it to a stock eb3 after a little porting.

Time is short right now as I am opening up my own business. I have not even worked on my own Civic for weeks. I have a ton of American v8 stuff to get out before I can get back to the eb's.

Allot of people are into flow figures. This is not the proper way to start with a competition engine. Port area should be measured first then the cfm figures will have some meaning.

Here is the general theory for what we are trying to accomplish. Treat the intake as a unit, from the tip of the air cleaner to the combustion chamber. Exhaust starts there and goes out to the end of the pipe. Figure out exactly how many cfms you need at what piston position. You want the cfm required with the smallest port area. Some engines require epoxy to fill the port rather than hog it out. Most comp engines require a custom cam lobes get the valve open fast enough. If you can do this then you try and use a short rod ratio, if you cant then you can crutch the engine with a long one. There are also areas about one stroke length into the intake port on a comp engine that need to be addressed. After all this is figured out then you can fine-tune the combo as far as wavelengths go.

A comp engine takes lots of time and money to do correctly, what we have been discussing with the eb2 head is mostly for someone who wants a play toy.

If you are serious, (are you serious?) get the engine design course from Allan and do some of the leg work. with the program sheets I provide. Or I can spend the time to do the figures and the research for you at a reasonable charge. Then we can do some practice ports to see if the results are attainable.

I have found that most people I talk to are dreamers, they want the "pie in the sky" engine but they don't want to invest the money into custom made headers, intake, camshafts pistons, rods, etc.. to really make the combo work. You can use the programs with existing parts or parts required by rules but the final product will be compromised. If you have to compromise too much you end up wasting your time.

| |

Don,

How much work have you done on forced induction?

(Best of luck with the new business, by the way!)

| |

Some supercharged Mustangs is all.

Forced induction is a whole different ball game. With a naturally aspirated competition engine, what ever makes it into the cylinder comes from the piston motion and atmospheric pressure. We need a small (relative) efficient port to effectively ram more air/fuel into the engine. This is how we are able to get over 100% volumetric efficiency. You speed up the mixture so that it retains inertia and then hang the intake valve open past BDC and the mixture keeps piling in for a few more degrees of crank rotation. This is why we need fast ramp angles on the cam; cause we have to get the intake valve closed quick to keep it from smacking the piston on its way up. The exhaust has to do its job fast too. There is “blow down” this happens when the exhaust valve first opens. You take a super heated combustion, with pressure and then all of a sudden expose it the outside (cool, no pressure to speak of) air when the valve opens and the exhaust wants to fly out of there. Provided that the valve is opened far enough at that particular point. It can work too well and suck out some of the incoming charge out with it.

With a supercharger/turbocharger its much more forgiving. Ports/headers,ect. need to be larger so as not to be the restriction and if you mess up with the cam timing you can cover up by boosting it more, provided the rest of the engine and the fuel system is up to the strain.

The bad part about forced induction is people expect it to be fast. With my last street Mustang it ran 11.64 in the quarter mile on street tires no NOS or turbo. There was always a mob of people asking questions (good for business). I have built other street cars that were much faster for customers, but because they used superchargers people never paid much attention to them at the street races and no one wanted to race them either ![]()

Of course a 1200 Honda turboed or not will not scare too many people away. You will be able to uses a short duration cam that will be really streetable.

| |

Just so you dont think I'm telling stories.

Yes, the front tires are off the ground.

| |

I never doubted your skills for a minute, Don. As you know too well, the number of people who can/will work on our little cars is dwindling fast. Besides, I'd rather keep my future engine work in the "family"-- defending one's choice of automobile can get a little tiresome sometimes. Thanks for the reply.

One last question: what brought you over to first gen. Hondas?

| |

No, the reason I posted the last post was that I was re-reading the last few post and it kinda sounded bragish or something.

Some of the reasons I sold my mustang (to a friend, so I can still take it for a spin ![]() )Was that I already had lots of USA work. I was enjoying the street grudge racing but bracket racing sucks, time for a change. I was fast filling my home garage with equipment as I had not rented a comercial garage yet, so there was not a lot of room left. Plus I wanted to corner some of the Honda market in my area. I figured a neet little 1st get would help do that, just like the Mustang brought in some of the drag racers.

)Was that I already had lots of USA work. I was enjoying the street grudge racing but bracket racing sucks, time for a change. I was fast filling my home garage with equipment as I had not rented a comercial garage yet, so there was not a lot of room left. Plus I wanted to corner some of the Honda market in my area. I figured a neet little 1st get would help do that, just like the Mustang brought in some of the drag racers.

I like all cars american and imports.

My business is auto repair first, as fixin late model auto's is the money maker. The hot rod stuff is a side line.

Here is a unfinished web page I started will have the real deal up at my Domian soon

http://www.rvi.net/~dforeman/vintage1.html

| |

Hi Don

Where do i contact Alan about engine design course

and would it be possible to get a program sheet. We have a strocker 1300, it goes reasonably well. Haven't had it on the dyno yet, we wish to build another motor in the near future.

| |

Yes I could do a program print out for you using the specs you decide on. The spread sheet is free but does not have as many functions as the real program about (1/8). I will send the spread sheet to you if you want.

The name of the course "Using software for engine design"

Allan Lockheed and Assoc.

PO box 10828

Golden,CO 80401-0600

Phone(303)-238-2414

| |

Thx Don,

What specs do u need for the spread sheet?? If u want ya can email me on- heydude007@bigpond.com.au

| |

Your confused, The spread sheet is free, not realy much of anything, but fun to play around with. It does have some useful info. The two programs that are used in the engine design course are Dynomation and Engine Expert. These are high dollar programs that work very well. There is a ton of info you have to provide. Thats why I told anybody thats interested to get Allan's Course, that way they would have a clue as to what onfo I need to make the program work and then know what they are looking at when they get the printout,from Dynomation and or Engine Expert.

| Administrator's Control Panel -- Board Moderators Only Administer Page |