| |

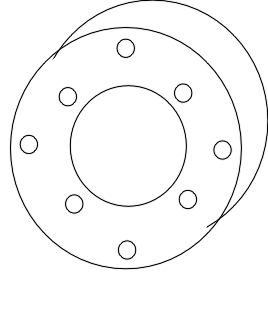

DOES ANYBODY KNOW OF A COMPANY THAT MAKES THESE?

| |

I don't think so but u could ask a machine shop do make u some spacers. Alluminum spacer 1 inches thick to convert from 120mm to 100 mm.

Anyway i'm sending u a pic from what i did myself few years ago.

If u need more info e-mail me.

| |

thanks

| |

Someone contacted me last week and said he had a machine shop convert his hubs and rear drums over to use the 4x100. Probably cheap to do, but they must get it perfect.

I'd suggest putting longer studs in there when you do this so you have the option to use a spacer later for tire clearance issues.

He's running 16s, don't have a picture of it.

I can't say I'd depend on an aluminum convertion to hold my wheels on for the way I drive my car.

| |

Much easier, cheaper and safer to get a machine shop to redrill your rims to the 4 X 120 PCD if rims are the only reason for the swap.

Datsun 120Y studs are longer and were used in a couple of conversions, the rear only require machining of the stub axle to suit the bearing from a second gen. Cheap, BUT the metal used in the later stub axles is a higher grade than the SB stub axles so you have to be carefull as machining them down will weaken them and predispose them to bending. A better option is to size the later model hubs to suit a bigger bearing. Often cheaper as it is easier to machine a nice round hub that fits easily in a lathe compared to the awkward stub axle. And you get bigger bearings!

The front conversion has honestly been beaten to death and is very straight forward (as listed elsewhere)

| |

I am the person mdouglas was speaking about. I had a machine shop re-drill the rotors and rear hubs to accept the 4x100 pattern and I currently have 16's on the car. I will be switching to 13's as soon as I can find an old set of BBS rims in the 4x100 pattern (shouldn't be hard, they were on a lot of HONDA'S and vw's in the 80's). Can anyone help me find a set, like to have an old set of race wheels (lightweight)? Back to my conversion, it went perfectly!!!!! Email me for photos. h2onut@vnet.net

| |

I have a set of 13x5.5 or 13x6 inch rims in the mesh pattern three are perfect but one has a dent it can be repaired. I did take it to a shop and it was going to run about $80.00. They are aluminum and off a first gen prelude. the other three are perfect. Sell for $50.00 and shipping.

Ramon

| |

Ramon,

wouldn't the G1 Prelude be 4x120? if so, and the wheels are 4x120 I'd be interested in them for my rally car project (G1 Accord)

drop me a line and let me know,

Paul

| |

Paul,

The G1 Prelude has a 4x100 pattern.

| |

nutz! I wonder why Honda decided on the 4x120mm anyway? I'm sure there is some secret numerology behind it.

guess I'll just have to get a set custom made when I decide I need either bigger or wider wheels.

oh well...

thanks

paul

| |

I think you will find that the Honda S series cars (S360, 500, 600, 800) used a 5x120 stud pattern, which just happens to be what Porsche used. When they made the Coupes (7 & 9) they went to 4x120, which flowed on to the Civic. I guess that when it became obvious pretty much every other small car manufacturer had standardised on 4x100 they switched over to that ...

| |

ok, I can follow that logic, but then how did they get to 114.3mm X 4 that they use on the Accords in the '90's?

I'm just wondering if there is some mystical number thing that I'm missing. guess it could be worse, we could have the 3 bolt pattern that you find on Renaults.

paul

| |

114.3mm = 4.5in. Many cars have used that size ... no idea what the logic behind it is though ... better ask a mechanical engineer (I might have been able to tell you if I'd bothered to stay at uni for more than a year).

| |

Charles,

So you're saying, leave the Gen 1 spindle alone and resize the 4x100 drums ('80 wagon, perhaps?) to fit the....Gen 1 bearings? Or are you fitting a different bearing altogether? What about the inner seal? Differences in bearing spacing?

You're right about the front, we've gone over it VERY thoroughly, but I still can't quite picture what exactly needs to be done for the rear. Thanks for the info.

Charles R.

BTW, the cam gear works perfectly. I just wish I was using the car more often this year.

| |

Charles,

The rear spindle in the SBs is a softer material and maching it down can weaken it. It would be a bit of stuffing around to get the bearings right, but it would only take 1/2 a day at a bearing shop and on a lathe. You may find something that swaps straight in with no machining. At least then in a race situation there is less chance of having to pull out with a bent stub axle.

Me personally, I would never swap the brakes for something less effective. The second gen drums are smaller than the first gens (except the wagon). If you go to the trouble of this swap, go straight to discs. We are still working on our 4 X 120 bolt on rear dics conversion to go with the 4 X 120 front disc conversion.

But although the standard first gen drums just look like dumb little drums they can be quite effective (especially when slotted and with decent pad material). The discs look far more professional but are little advantage on a car with as little rear weight as a 1200. Less chance of locking up though and better brake pedal modulation.

Charles

| |

This is my way of doing the rear (there are other ways of course):

Use EN1 wagon (200mm) or sedan (180mm) drums and backing plates. I use the wagon brakes, but the smaller sedan brakes may be better if you don't have a bias adjuster. Use the EN1 bearings and grease seal. You modify the EB stub axle by pressing a sleeve onto the inner part of the stub to accept the slightly larger EN inner bearing and machine a tiny bit off the outer part for the smaller outer bearing. This way a minimum of material is removed from outer bearing surface of the stub axle only, helping to preserve as much strength as possible. You then make up a 5mm spacer for behind the backing plate and redrill the mounting holes in the backing plate. You now have a stub axle onto which standard EN1 drums will simply bolt on.

| |

Who has those press on sleves and how much are they??

| |

I do. It's not just a matter of pressing them on as there is machining to be done once they are in place. I can only supply complete stub axles for approx. AUD$150 pair (exact price depends on how much I can find some second hand stubs for), plus postage. If you want a complete conversion with spacers, backing plates etc., I can do that too. Price depends on cost of raw materials, but if you aren't in Aus, postage can be a killer.

| |

How much to ship it to The US? Just the complete stub axle. Do you also have the Mugen adapters?

Thanks

Ramon

| |

Yes (basically the same as the Mugen brackets), AU$200 pair. Postage for two stub axles and two caliper brackets should be about AU$80.

| |

I would like to get them lets Talk.

Ramon

| |

hey, rekindling the rotor thread ..

does anyone know if the 76-81 accord rotors are similar to the 78 civic rotors/ what's the diff?

also, i don't really understand all the bolt pattern stuff .. i mean, it seems there is a lot of explanation here, but how complicated is the conversion REALLY .? how much would it end up costing?

thank you for any info

| Administrator's Control Panel -- Board Moderators Only Administer Page |