Shreck’s Project

This is a post that follows the restoration of my 1978 Honda Civic. The 1200 Civic hatchback is a restomod built for my personal Sunday drives and car shows.

I purchased the 1978 Honda Civic in July 2002 from Cobourg Honda in Ontario Canada. It has 134,000 original kilometers. Gold exterior, AM/FM radio with 2 door mounted speakers (looks like dealer installed when new). Purchased by dealer from the original “elderly” owner in 1996 for display in their showroom. It was repainted in 1997 in the original gold color in base coat clear coat, since the original owner had the car painted white and this was the only way she would buy the car when new.

Interior Condition

The interior is very clean with all original vinyl and carpet in excellent condition, the drivers seat was replaced with the covers from a passenger seat of the same colour car. The car sat 3 years in the dealers showroom until the space was required to display current models.Many new parts including front calipers, hood, rear hatch, door, fenders, bumpers and filler panels. Took me about 1 week and $95.00 to get it certified. Parts I had laying around including 2 drive shafts, 1 upper strut bearing, 1 tie rod end, front strut and lower ball joint. New parts included 2 rotors, pads and tires (the tires witch I stole from my restoration project car

Its a good looking original First Generation Civic considering it is from Ontario as most of them have the floors and rocker panels rot out of them in one place or another. They tend to rot in the corner of the windshield as well letting water in to continue the rust process on the floor pan.

Disaster Strikes

Since I took these pictures, I drove the car for only 2 days after certification (Sept 2002). This is when I found that the cast mount on the drivers side of the engine block was broken right off.

The camshaft key way and camshaft wheel is badly damaged. I can only assume that it came loose from vibration from the broken engine mount.

The timing belt was also chewed up. This is what it should look like on the far right.

The timing belt was also chewed up. This is what it should look like on the far right.

Checking a little further, this is not the original motor, it should be an EB3 but in fact has a EB2. Someone at Cobourg Honda must have done an engine swap with a defective mount. I checked over the car and could not find any damage to the body to verify it had been in a collision. This is usually how the mount breaks. It also had a rebuilt automatic transmission put in a some time. On further examination I noticed that one of the starter bolts was loose and the lower one was hanging out. When I removed the rocker cover all the front rocker screws were damaged as if it had been knocked over somewhere.

After some serious thought I wanted to keep the car original, I had an extra EB3 engine, I took it in to Scarborough Engines to have it rebuilt but could not source over sized pistons. Many years ago they were a major re-builder for Honda. I also have a 5 speed transmission w/chrome shifter from a Special-X to put in during the swap. The motor sat for three months at the shop at which time I ran into a chap that was racing these cars at Mossport dry raceway and on ice during the winter. He had 4 ice racers and one stock car. (2 ice racers were rabbits)

This is what a typical mount would look like to replace the broken off motor mount. This one bolts on the ends of the head beside the distributor and on the opposite side. I could not find one of these at the time the damage was discovered, otherwise I would have taken this easily resolved solution.

Timing belt debris on right of engine bay from when the camshaft wheel came loose and wobbled part of the belt away and damaged the key-way to an in-usable condition. Some mechanic had tried to make this do by drilling deeper holes and tapping it, this was a total failure as there were only 2 threads and the other bolt was just sitting in the hole resting and waiting to fall out. None of the broken off parts were found under the timing covers which is a good indicator of a failed job unless this was done to deceive the owner at the time offering an engine swap with a defective block that could have very well come from a written off car as these mounts easily break during a side impact. This was a totally botched job to just pawn the problem off onto some one else. However the motor runs very well and does not blow smoke or make any unusual noises.

Parts I need for my spare EB3 rebuild: Over sized pistons, at this point I am willing to take any range of over sized pistons. The pistons are difficult to find locally but can be custom made at a much bigger expense, approx $420.00+ US. Other parts needed are rocker shafts and 2 rockers that are also hard to find so I will be re-cycling some used parts from another motor. Pretty much I have most of the other parts new such as complete oil pump, water pump, valves and guides and new bearings. Gaskets are pretty easy to find if you keep your eye on line auctions.

Engine Swap

Below in the video my son is hiding in the garage while I talk with the previous owner of the motor to figure out why it runs so rough.

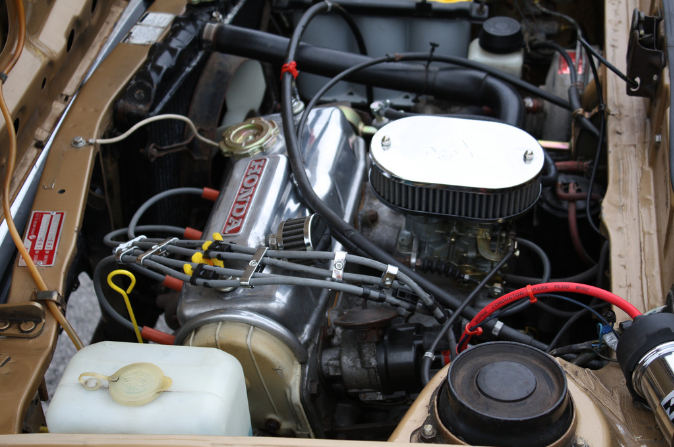

Well I didn’t get my EB3 rebuilt, for a lack of finding over sized pistons, instead I bought a newly rebuilt motor that came out of Jeff Wenzel’s Ice Racer, previously rolled. It’s only run about 50km since the motor was rebuilt and all I had to change is the oil pan as it had a tiny rust hole. The bottom and top end of the motor is spotless. It is an EB3 Motor with and EN1 head from a second generation Civic.

The Mugen valve cover will fit any of the first generation Honda Civic heads being of the EB1, EB2 or EB3 types including the second generation Honda Civic EN1 types too. This will not fit the CVCC Engines.

Here Colin Kennedy is helping me trying to set up the timing and the Weber carburetor. In the end the timing had to remain advanced by about 28 degrees plus. I found out later from the guy I bought it from that it has a racing camshaft shaft and he kept it at about 35. He said it is going to be difficult to take this motor and put it back to street use with out too many problems. One thing for sure is the exhaust is too small as I am using stock, I noticed that starting is difficult but for some reason when I had the muffler off it started first shot. I have taken the Weber off the car and put the stock carburetor back on and this seems to have helped a bit.

Turns out after a little research that the 28DCD Weber carburetor is used in the UK or European countries on the Ford Cortina. No wonder I had problems with it. The adapter is a standard Weber intake manifold adapter for the Cortina, however it has been welded to the Civic one since the bolt holes do not line up correctly.

Engine Swap

I have prepared to pull the motor, Removed the grille and hood as well as disconnecting the shifter linkage and carburetor choke and accelerator cables.

This is my EN1 head W/broken off mount | EB3 head for 78-79, note the differences EB3 heads have an “H” stamped on the front passenger side while the EB2 has a “S” in the same place. As for the broken mount I will be using a modified transmission bracket from an second generation civic for the torque rod to attach to.

I fabricated a bracket for the torque rod to fasten to, picture on the right was my second shot after breaking the first one a couple of times, It kept on breaking the bracket that bolts on through one of the starter bolts and one of the transmission bolts. I had to double up the thickness of the Honda bracket to take the torque. I then attached the old outer torque rod bracket and attached a rod from it to the manifold which seems to be holding quite well so far.

The bracket would still bend away from the head causing the muffler to break off as well as bending the strap that holds the downward exhaust pipe. This is also my second muffler, The first one broke off right at the muffler.

Here is my new design, you can see I used a stock bracket and flipped it with a 3/8″ rod with a bracket on the manifold. This method is really strong.

The bracket would still bend away from the head causing the muffler to break off as well as bending the strap that holds the downward exhaust pipe. This is also my second muffler, The first one broke off right at the muffler.

Here is my new design, you can see I used a stock bracket and flipped it with a 3/8″ rod with a bracket on the manifold. This method is really strong.

Here is my first attempt at making the bracket work. Bummer total failure, the torque from the motor causes the A bracket to bend away from the head causing the mount to break the metal tab used to attach to the starter motor bolt. I welded it back up, this time the tab is about 1/4″ thick and the other leg of the “A” has to be beefed up as well as it broke the leg off.

I bought this oil filler cap on the internet on line auction. I am not sure if its a Honda

Original or just and aftermarket creation. Its a little rare, but I don’t think there is much value other than its just different. I ended up buying new original OEM old filler cap that looks a lot nicer because of the shine I guess.

As you can see I have not used the Mugen cover. I purchased this nice polished cover instead because I am looking for a different look. I just need to get rid of that dirty breather.

Before and after shots

Cooling System

The radiator is in very poor condition as you can see parts of the core have fallen out already. I got the radiator re-cored at Kawartha Radiator (Johns Garage) in Lindsay for about $175.00, it has a new copper core and should last as long as I own the car.

Downdraft Carburetor

Weber 32/36 DGV down draft series of 2 barrel carburetors are available with various throttle bore sizes, and manual or automatic chokes. These will give that quick throttle response you are looking for, they also have larger barrels and venturi than the stock Honda carburetor that allows the engine to produce greater power at a higher RPM. Weber kits can be found at carburetor Unlimited

Weber 32/36DGV (Manual Choke)

Weber 32/36DGEV (Electric Choke)

Here was a deal, $165.00 us for a Weber 32/36DGV manual choke carburetor. I only wish I had bought one more at that price.

This kit is easily put on and includes all the parts needed to get you up and running in no time

Weber 32/36DGV (Manual Choke)

Weber 32/36DGEV (Electric Choke)

Here was a deal, $165.00 us for a Weber 32/36DGV manual choke carburetor. I only wish I had bought one more at that price.

This kit is easily put on and includes all the parts needed to get you up and running in no time

It also includes the bracket that goes on the intake to hold the throttle cable. This is a good carburetor for the every day enthusiast looking for more power and performance. This is not the best one to use if planning some serious driving as this Weber has problems in the corners at high speed.

One modification I have to do is to remove the area of the intake that the adapter covers, I just have to remove the material in the opening of the adapter. This will also give me better performance as well. This was a good time to replace all the old vacuum lines.

To install the accelerator cable is possibly the only difficult thing about installing a DGV Weber on your old civic.

First get a piece of metal about 1 inch wide by 4 inches long and about 4-5 mm thick. drill a hole in either end about 8mm or so (I am not sure about this).

Then make 2 bends, one about a centimeter above the bottom hole of your choice, and to the right at about a 45 degree angle. then one more about a centimeter below the top hole, so that when the bottom is attached underneath the nearest intake manifold bolt, the top hole is totally facing towards the linkage area. this may need a little adjusting. you may also want to cut a slit a few centimeters wide from the top into the top hole. makes it easier to get the cable in. The accelerator cable can now be screwed into the hole at the top. there you go. Weber throttle cable bracket for the 1200.

One modification I have to do is to remove the area of the intake that the adapter covers, I just have to remove the material in the opening of the adapter. This will also give me better performance as well. This was a good time to replace all the old vacuum lines.

To install the accelerator cable is possibly the only difficult thing about installing a DGV Weber on your old civic.

First get a piece of metal about 1 inch wide by 4 inches long and about 4-5 mm thick. drill a hole in either end about 8mm or so (I am not sure about this).

Then make 2 bends, one about a centimeter above the bottom hole of your choice, and to the right at about a 45 degree angle. then one more about a centimeter below the top hole, so that when the bottom is attached underneath the nearest intake manifold bolt, the top hole is totally facing towards the linkage area. this may need a little adjusting. you may also want to cut a slit a few centimeters wide from the top into the top hole. makes it easier to get the cable in. The accelerator cable can now be screwed into the hole at the top. there you go. Weber throttle cable bracket for the 1200.

Ignition Coil

Use of the Pertronics or MSD Blaster Coil to boost voltage and gives a better spark. It improves to 40,000 volts, the higher voltage allows larger spark plug gaps for added power, smoother response and better fuel economy. Delivers an average of 15% more spark energy and voltage. It's just a regular 1.5 ohm coil with built-in ballast resistor to a total of 3 ohms, or stick with the stock 1.5 ohms coil and keep the ballast resistor.

OPTIMA Gel Battery

Gel batteries don't need much maintenance, can be placed in any place or position. Gel batteries are also resistant to vibration and shock. They don't produce hydrogen fumes so you also don't need to worry about placing them in a special ventilated area while charging them. Being deep cycle batteries they have got a higher discharge feature. The best feature for me is that a gel battery can be revived even if they are left discharged for some time unlike the wet cell batteries. Another advantage over lead acid battery is that it doesn't develop a memory which reduce battery capacity to recharge.

Adjustable camshaft Gears

The whole point of adjustable camshaft gears is to allow the user to put the camshafts into the optimum timing position. But what is optimum for your car? The answer is, it depends. Engine size, camshaft profile, performance modifications, any of these will affect the optimum position for your camshafts. If you pull your cylinder head and have it milled, you'll surely be interested in adjusting your camshaft timing back when you find out you're a few degrees off without having touched anything else.

Even if your car is absolutely bone stock, right down to the floor mats, you can still benefit from the use of adjustable camshaft gears. Adjustable camshaft gears allow you to tweak the conservative factory settings for increased power and drive-ability. Adjustable camshaft gears also give the user the ability to shift peak power throughout the rpm range, a big plus if you are a low-end city driver, mid-range auto crosser, or high-rpm drag racer.

I will get this one of these days.

Even if your car is absolutely bone stock, right down to the floor mats, you can still benefit from the use of adjustable camshaft gears. Adjustable camshaft gears allow you to tweak the conservative factory settings for increased power and drive-ability. Adjustable camshaft gears also give the user the ability to shift peak power throughout the rpm range, a big plus if you are a low-end city driver, mid-range auto crosser, or high-rpm drag racer.

I will get this one of these days.

Exhaust

Next job on to bigger exhaust then on with the RS Header.

Interior Accessories

Below are some goodies I bought from Jeff, left a Momo rubber grip racing wheel, and below Cheviot 13×5.5 rims. This MoMo steering wheel for a first generation Honda Civic can easily swapped for the stock steering wheel. It turns out that the horn did not work when making a right hand turn. Now why is that, could have something to do with the use, I can only guess that making constant turns on an oval track is why the contact plate for the horn was worn through to the underlying plastic.

Solution: Bend the contact arm to make it longer or shorter so that it does not ride in the worn out grove.

Suspension

The front suspension was removed and axles pulled as new shocks, strut bearings including strut tops and rotors and bearings were to be installed while the motor was out. The steering rack was pulled too as I wanted to install a rust free newly painted rear cross beam.

Steering Knuckles

I had started to refinish these steering knuckles for my other car but decided to use them on this car as they were already removed and ready to go for new bearings and seals.

Finished and ready for new bearings

The rear engine cross beam are mostly rotten and full of holes in Ontario junk yards if you can even find one, I have gone through 3 and all are badly rusted, it is hard to tell until you get if off and then find there are holes in the top. The one on the right I bought from Vancouver Canada and just had to cleaned it up a bit and repainted it. The one on my other project car has a big hole through one end close to the control arm.

Pictures below give an example of before and after. These are pretty rusty given the amount of road salt that is required to keep roads safe in the winter months. I replaced the rubber on the shifter and pedals too.

Shocks

This is the funny stuff, the new shocks I bought up from California for the front and rear. on line auctions

I replaced the front ones right away, but when I was asked to take some under car pictures of the rear wheels is when I noticed that something strange was going on. The picture on the left is the actual back of my car, that’s a CVCC rears suspension, I am very surprised to see it on a 1200 Civic. The U shaped shock is for the 1200 where as the CVCC bottom has no bracket similar to the front shocks.

CVCC rear shocks

I replaced the front ones right away, but when I was asked to take some under car pictures of the rear wheels is when I noticed that something strange was going on. The picture on the left is the actual back of my car, that’s a CVCC rears suspension, I am very surprised to see it on a 1200 Civic. The U shaped shock is for the 1200 where as the CVCC bottom has no bracket similar to the front shocks.

CVCC rear shocks

1200 rear shocks

Turns out that, (Colin) The lower control and trailing arms + the shocks and rear brakes in your car are from a 78 CVCC hatchback that the dealership acquired for parts in 1998. The shock spring mounts were rusted bad on the original shocks, so we just changed everything on both sides. To be honest, I never noticed the difference when I changed them, but it is pretty apparent now.

Stereo and Console

During the cold days of February 2003 I fixed up and recovered a floor console from a scrap car I bought during the summer of 2002.

Found a good old Sony stereo cassette to fit in. I am to going to get another gauge to put beside the oil pressure gauge. You can’t see it (covered up until I am ready to put it in) but this console has a spot for toggle switches or pilot lights.

Unfortunately the glue used to attach the black fabric was of poor quality and it came unglued.

Unfortunately the glue used to attach the black fabric was of poor quality and it came unglued.

New OEM Honda Civic rear mud flaps.

I attached them stainless steel 10mm bolts and nuts, I concealed them black under plastic bolt caps that can be bought at Home Depot in the bolts section. The caps can be easily removed at ant time and blend in perfectly with the mud guards.

New OEM Special X mirror, The Special X Honda Civic was only sold in Canada. One was not enough, I had to buy two of them. One of them is in my Trophy Case with new Special X wheel caps.

Special X Tachometer Cluster and Center gauges.

A sweet trade for a 76 overhead console as seen in the picture below.

I cut out the wood grain section in the middle of the dash to find a blank filler plate that is easily popped out to access a wiring harness to the left of the opening, If I remember correctly it was taped to the main harness.

A sweet trade for a 76 overhead console as seen in the picture below.

I cut out the wood grain section in the middle of the dash to find a blank filler plate that is easily popped out to access a wiring harness to the left of the opening, If I remember correctly it was taped to the main harness.

7/30/04 recent improvements include Prelude seats an overhead console and a wooden 3 spoke steering wheel. Polished original valve cover to replace the dreadful looking Mugen one.

One thing to consider if looking to acquire an overhead console for your first generation

One thing to consider if looking to acquire an overhead console for your first generation

Honda Civic is the years. The 73-77 console is slightly narrower at the end where the done light is covered up. Using the old one will leave a minor gap where your old dome light was removed. The older Civic use a round dome light, where as the 78-79 uses a rectangular dome light. It’s like putting a circle in a square, you will have spaces at the edge.

Images of 78-79 and then 77 and older Civic and last is the console from a N600 coupe, notice how similar it is to the earlier Civic type less the clock.

Some of the clock's don’t work so well but these can be repaired or you can re-calibrate it your self.

Images of 78-79 and then 77 and older Civic and last is the console from a N600 coupe, notice how similar it is to the earlier Civic type less the clock.

Some of the clock's don’t work so well but these can be repaired or you can re-calibrate it your self.

I bought this wooden steering wheel from an auto wrecker in Oregon when I inquired

About other parts I was originally looking for. This is from a 1977 CVCC Civic. I also pick up some rust free door handles and rear license plate lights and scored a tachometer and center dash cluster gauges.

I stripped the old varnish off the wheel and too any rough edges of. The metal spokes were also repainted. This wooden wheel and shift knob gives the car a real classic look.

Wooden shift know to go with the newly acquired steering wheel. Seems to be made of a soft wood and capped off with a brass insert for the five speed.

I have since restored the shift knob and repainted the brass insert to it original colour.

I stripped the old varnish off the wheel and too any rough edges of. The metal spokes were also repainted. This wooden wheel and shift knob gives the car a real classic look.

Wooden shift know to go with the newly acquired steering wheel. Seems to be made of a soft wood and capped off with a brass insert for the five speed.

I have since restored the shift knob and repainted the brass insert to it original colour.

Ah! Seat swap, Nice and comfy and a great back support with side bolsters. These seats are from a 91 Honda Prelude. I used a combination of the original Civic rails along with one of the Prelude rails. I removed the inside sliders and welded a flat bar from the outer rails to the inside bar. This allowed me to bolt the Civic stock rails in place.

Wheels

It still had the stock size tires (155/80 12 inch) that were badly cracked in the side walls, and I have future plans to upgrade to better tires. The center wheel caps were missing the typical red paint so I cleaned and repainted them using a good artist paint brush and enamel model paint. Finding the stock tires can be a bit of a challenge depending on where you like. Dealers said they could get them from a Korean company or bring them in from the USA. Not even places like Canadian Tire stock this size. Pay a visit to Wall-Mart auto center and you will find them in stock. You may even find a wider flavor of our 12″.

Wheel Restoration

I am hoping that these worn out old Cheviot 13″ wheels can be brought back from this horrid state of condition. Many years of racing have left scars on the aluminum wheels. Most of the fake screws are missing from the outer diameter of the wheels.

Finally got around to refurbishing these old beat up Cheviot 13×5.5″ wheels, This size can be found on the Accords if you are looking for some in the 4×120 bolt pattern.

I started of by using a coarse flat file to take the gouges out, followed up by the use of a Drumel tool to get at hard to reach places in between the webbed patterns. The use of many grades of water paper can make this job go a lot quicker and less work. I started off with 40grit 60,80,120,240,400,600 and finished of with 1200grit. A final chrome like finished was obtained by using Mother’s Aluminum Polish.

To get the Honda Civic Stock wheel caps to fit the Cheviot wheels I filed off the ridge from the opening, Minor bending of the cap tabs was also done. To help the cap maintain a tight fit I drilled 1/8″ divots inside the opening for the dimples on the caps to sit snugly in.

Before the final finish can be applied the outer polished areas are taped up with Duct Tape. This is done to protect the finish from the sand blasting that will remove the old paint and even out the rough areas that were repaired.

I started of by using a coarse flat file to take the gouges out, followed up by the use of a Drumel tool to get at hard to reach places in between the webbed patterns. The use of many grades of water paper can make this job go a lot quicker and less work. I started off with 40grit 60,80,120,240,400,600 and finished of with 1200grit. A final chrome like finished was obtained by using Mother’s Aluminum Polish.

To get the Honda Civic Stock wheel caps to fit the Cheviot wheels I filed off the ridge from the opening, Minor bending of the cap tabs was also done. To help the cap maintain a tight fit I drilled 1/8″ divots inside the opening for the dimples on the caps to sit snugly in.

Before the final finish can be applied the outer polished areas are taped up with Duct Tape. This is done to protect the finish from the sand blasting that will remove the old paint and even out the rough areas that were repaired.

To sandblast I created a small area in the garage with blue tarps with weights on the bottom. or you can use plastic shower curtains from the dollar store that have weights built in already. After the sand blasting I cleaned the wheels with mild soap and a pressure washer to clean them up. I left the duct tape in place while cleaning.

I went down to the local Napa auto parts store to get my cars colour mixed and put in two pre-charged cans for easy application. I also bought clear coat for wheels, but the type I used must be applied while the base coat is slightly tacky. I removed the Duct Tape after the base coat (colored) was applied. The area where the tape was cleaned with paint and silicone remover. I put several coats of clear coat on the entire face of the wheels. When the clear coat goes on its a milky colour, Don’t panic now, it clears up as it dries.

I went down to the local Napa auto parts store to get my cars colour mixed and put in two pre-charged cans for easy application. I also bought clear coat for wheels, but the type I used must be applied while the base coat is slightly tacky. I removed the Duct Tape after the base coat (colored) was applied. The area where the tape was cleaned with paint and silicone remover. I put several coats of clear coat on the entire face of the wheels. When the clear coat goes on its a milky colour, Don’t panic now, it clears up as it dries.

Tires

Finally its time for some cool performance tires. It was not easy to find descent tires that I wanted for summer use only. I went with Falken ZEX502. I waited a long time to get these as they were discontinued at the time I ordered them. The dealer ordered them in from the Falken warehouse in Quebec but when they arrived at the dealer they all had gouges on the inside of the tires. Turns out they had been returned because they did not fit someone’s application. There were no more of these in Canada so Falken found them at dealers in the USA and paid the shipping to my dealer.

Steering Rack Rebuild

While you have the unit apart it you could adjust the play in the gear by releasing the large lock nut on the bottom and adjusting the bolt. You can feel the play as you turn the shaft. Don't make it tight, and it make take a while to get it just right. Remember to tighten the lock nut when finished making you adjustment and retest to make sure the gear and still be turned by hand.

During assembly of the tie rod ends I measured and put them on in the same spot as the old ones.

Now get it back in with out scratching the paint.

Remember to get you alignment done after this procedure. To get it straight I used a measuring tape with the steering wheel still straight with the bungee attached, I measured the front edge of the tires from center to center. Then measure the same on the backside. I left the front side of the tires a bit narrower than the backside.

As it turned out when I took it in for alignment it was perfect. The garage only charged me for setting it up.

To see more of my steering rack rebuild Diy you can see it here:

viewtopic.php?t=9260Now get it back in with out scratching the paint.

Remember to get you alignment done after this procedure. To get it straight I used a measuring tape with the steering wheel still straight with the bungee attached, I measured the front edge of the tires from center to center. Then measure the same on the backside. I left the front side of the tires a bit narrower than the backside.

As it turned out when I took it in for alignment it was perfect. The garage only charged me for setting it up.

To see more of my steering rack rebuild Diy you can see it here:

With this new handy Led light there will be no more cooking from the heat off the old Halogen light.

With this new handy Led light there will be no more cooking from the heat off the old Halogen light.