Because i made several mistakes,its now time to tell,so that others wont

Deu to not reading the 4x100 how to on this site i mis used things.As pinions and control arms.

When i assembled my 2nd gen knuckles onto my sb1 i noticed that my new bearing had some "play"on it

When i drove it,the brake disk even scratched the caliper.

WHY :shock:

Settled for a couple days,and took it apart.

What went wrong.

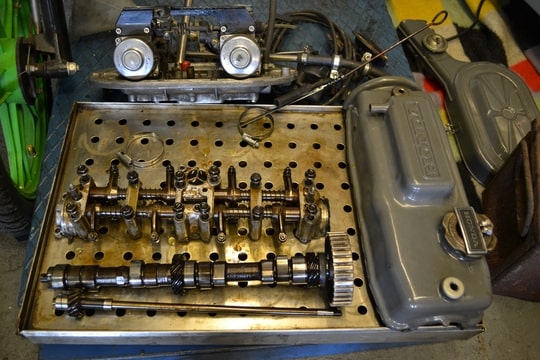

After measuring a lot,i found out that the splines on the pinion are not long enough.In stead of locking the bearing,it now locked the splines.

Again did some research here and read about this.

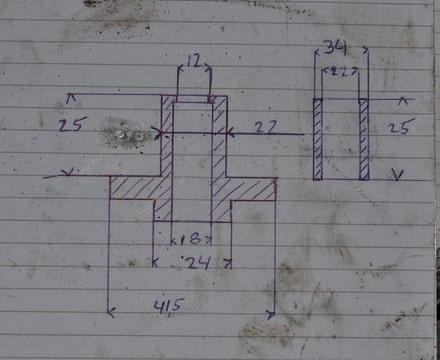

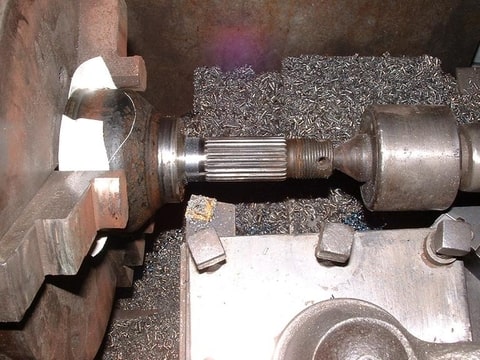

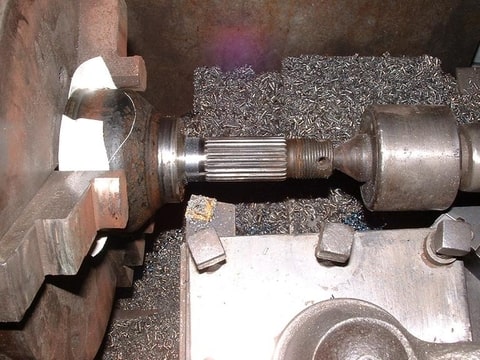

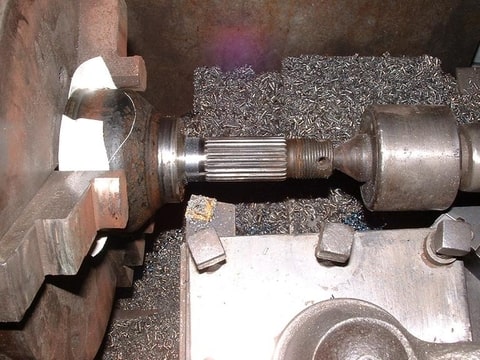

In stead of putting on some 2nd gen pinion it put it in my lathe.

Just to be sure the pinion would slide in to the knuckle far enough

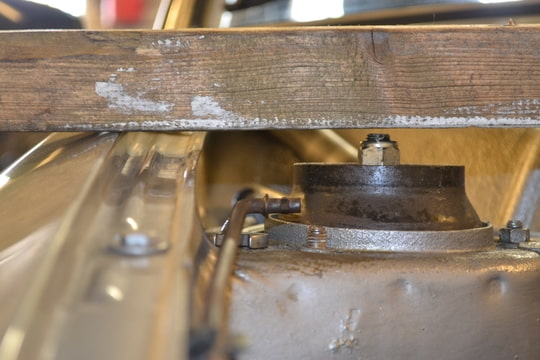

Fit it al together ,and yep...its does the trick!!

Drove it again.No scraping sound anymore luckely

Stil it did not drive good.Loads of feedback on the steering wheel.

Why????

I had it lined out at a shop.

Found out that i had way to much positive camber.

Why....

1stgencivic.com.....thanks again for the info.

Problem,i had to use 2nd gen lower arms,to compensate the knuckle.

But ,why not do it differend.

I was checking the scrap metal containers at work and found something i could use almost plug and play.

I only made the square part.Its just a solid block of metal ,with i drilled and tapped.

Something anyone can do with minor tools.

Than take a control arm.and start cutting..

And start welding TIG.

I cut out the rubber bushing out of the scrap piece control arm.I'm re using it,and put in my home made arm.

Than re alligne

And drive!!

Doing 4x100 swap the right way

To share some some info to you guys.

Here by a pictorial on how to swap to 4x100

On this site is already a tutorial on how to do it,BUT I dont like this one

viewtopic.php?t=12530

Why is it that i dont like this one,I'v done it.But took it of after riding it and realignment .

Due to the fact that you use the lower control arm and 2nd gen hub ,your wheel span wil change big,it will widen out a lott!!

Now you will not be able to put wider wheels on your car.Your positive camber is still there .So steering is BAD.

This is what i recomment,this is what I think is best.

You can give reply's if you think I am not right,I dont mind

What do you need:

1st gen knuckles

1st gen brake calipers

2nd gen disk brake

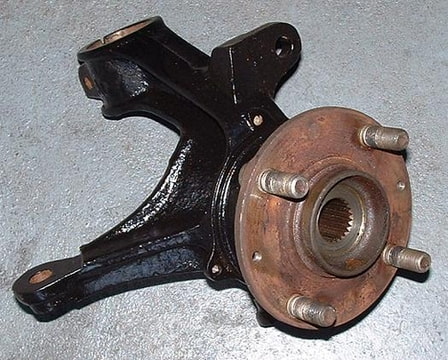

2nd gen hub(4x100)

Wheel bearing (1st or 2nd gen ,both will fit)

2nd gen 80/83 pinion or modify the 1st gen item(shown later)

This is what a 2nd gen hub looks like with dust seal of 1st gen on.

1st gen dust seal on 2nd gen hub

1st gen hub with 2nd gen seal and visa versa

So now you know its fits!!

2nd gen knuckle and 1st gen knuckle

1st gen and 2nd gen bearings,both wil fit in 1st or 2nd gen knuckle!

Now beforen pressing it all together ,you need to shorten the bolt heads of the dust seal.When the 1st gen hub is fitted on the knuckle you got clearance couse its 4x120,so more space.

The 2nd gen is 4x100,so 20mm less clearance.

Grind of the bold heads,that is the easy way

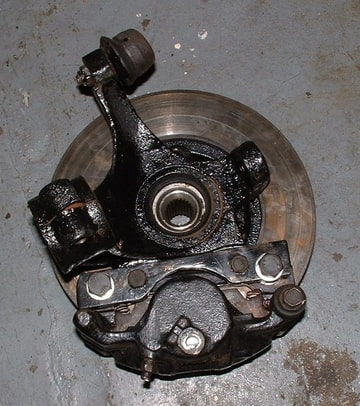

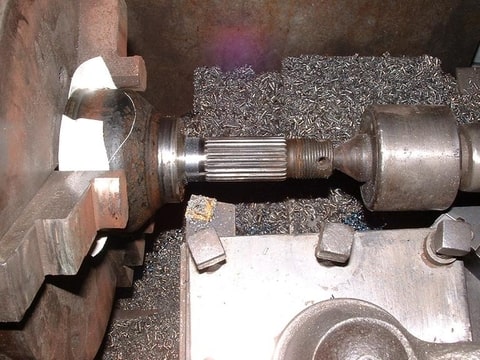

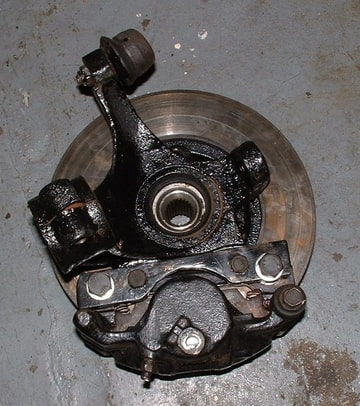

Than put it al together,2nd gen hub in 1st gen knuckle

Than put 2nd gen disk brake on,and 1st gen brake calipers.

Now you are almost done

The pinion head of the 1st gen will not fit the hub,the splines run all the way on 2nd gen hubs,1st gens run 2/3 the way.

So you need to swap the pinion head to 2nd gen 80/83 on your axle.

I like it easy,1 just put my pinion my lathe,and made more room on the spline track.Just made it a bit deeper,so the splines of the hub wil slide further on de pinion head.

I even made the swap better:

what i used

1st gen knuckles

2nd gen hub

2nd gen bearing

civic 92 brake booster and main cillinder

civic 92 vti brake calliper and disk

home made bracket