|

|

|

|

|

|

About Rust |

Rust

So we are all in this together, an all out war against rust,

is the eternal enemy and finding effective ways to eradicate

the evil annoyance is the Holy Grail of this crusade. So?.

What is Rust?

Rust, Corrosion, Metal Cancer, grot--rot or properly called

iron oxide. It's the stable form of steel. Iron ore, the raw

mineral we mine to make steel, is actually iron oxide. Rust!

Yes, steel is made from rust. It spends the rest of its life

trying to return to its natural state.

In order to have rusting take place, you need three things:

Steel, Oxygen, and Heat. Rust is actually an electron

exchange; Steel gives up an electron and becomes rust. It's

a process related to electricity. In fact, anywhere two

different metals touch, there is an electrical current

generated.

Where to look for rust

You don't have to look very far if your in the snow belt, if

you have made a trip to the scrap yard and you happen to

find one of these old butes chances are you found what I

did, not much, except some descent plastic parts and rubber

bits. If you are really lucky you might find some nice

preserved engine and transmission parts preserved in a thick

black coat of grease and oil.

The most likely areas to check for rust would be in and

around the wheel wells and on the windshield pillars, front

floor below the fuse box and stock speaker location. Under

the rear points where the front fenders bolt on and in the

front locations just behind the headlights to the sides.

Inner and outer rockers panels. These are the major war

zones where to look for the rust fungus. If you happen to

own a pre 78 I believe you will be in worse shape cause Honda

did not put inner liners for the front fenders and chances

are there are going to be some rot under there too. Can be

nasty, just ask Vulcan, he knows and he is fighting back.

If you are looking at purchase one of these gems use a

flashlight to look underneath the car behind the front and

rear tires on both sides, you may want to poke at the

undercoating for crispiness as it can be deceiving to the

eye Of course, before you do this make sure the of the car

says it's ok to go poking around & the car is parked on a

level surface in park/gear and the emergency brake engaged!

Shine your light on the inside of the fenders and wheel

wells.

Check for excess body filler, which from this side will look

like hardened putty all globbed up. In areas where you don't

have a clear view, use your fingers as your eyes and feel

around. Do you feel globs of hardened putty under there? If

so you're looking at a likely rust repair job.

Now you can use the sound test to decipher how far up body

the filler goes. Above the suspected area, tap lightly on

the car's body with your knuckles. You should hear a tinny

metal sound. Continue tapping and move slowly down to the

area in question. Does the sound change from tinny to solid

and dense? Where the sound changes is where the filler

starts.

Once you have detected a major rust repair job you may want

to stop your inspection and find a rust--free car from our

friends in the south or west coast because eventually the

rust will come bubbling back up through the paint. The car

may look great now, but if it looks like Swiss cheese in a

year, you'll be the crying loser in the end.

Another quick word to a buyer:

Avoid cars with fresh paint. Think about it. No one paints a

car just because the color has faded a little. It was

painted because it was either in an accident or it had a

rust problem or worse yet - both! A body man can hide a lot

of sin with paint and body filler. Be wary. However keep in

mind that these classics may have been paint up to 4 times

in its life span.

Other rust--prone places to check when buying, would be the

exterior flooring under the driver's and passenger's seats,

the interior flooring underneath the carpeting/matting,

under the matting in the trunk, and around the engine

compartment. Use your flashlight, your eyes and your

fingers! Be Careful Of Jagged Metal.

What to believe!

The way rust usually begins is through the chips and nicks

you receive from the pebbles and stones that pepper your car

through daily driving. With a small nick exposing bare metal

in an unnoticeable location, it's just a matter of time

until rust forms. Left unchecked long enough it will eat its

way through to the other side. When this happens you have

problems because once a rust hole starts it cannot be

stopped. It can only be slowed down or cut out. Cut it out

only when it becomes a cancer!

RUST IS CAUSED BY ROAD SALT!

"Top Ten" causes of rust in the snow belt, road salt would

barely make it to the middle of the list. (Road salt causes

what is known as "poultice rust", where salt traps and

retains water in a fixed spot for extended periods.)

In fact, the #1 cause of rust is condensation, the invisible

moisture that forms inside the car's panels due to

temperature changes.

If you leave your car parked outdoors, you will notice

condensation on the windshield first thing in the morning,

even in July. This daily "condensation cycle" creates water

which gravity then pulls to the lowest points inside your

car's sheet metal -bottoms of doors, lower trunk lid,

boxed--in fender areas, etc. Some experts call this the

"bathtub effect" -since the moisture has no place to escape

to, it stays in contact with the metal. In winter, the daily

temperature changes are much more extreme -especially if you

park inside a warm garage -so the effect is greatly

enhanced.

Additional rust problems arise in extreme cold when the

already--present water pockets expand (the same way ice

expands in your freezer) thereby rupturing the existing

factory sealants. "Electrolysis" is also an important issue,

because areas on the body with extra metals (as, for

example, where a door handle, trim piece, or mirror are

attached) generate more current, which in turn, accelerates

the rust process in that particular area.

NEW CARS DON'T RUST!

Put this in the "wishful thinking" category. Great strides

in corrosion resistance have been achieved at the factory

level, but new cars will start to rust from approximately

their third or fourth year onwards. The process is

complicated by the fact that rust works from the inside out

-the so--called "iceberg phenomenon,"-which suggests that,

by the time you actually see bubbling on the outer sheet

metal, it's really much too late.

MAKERS WARRANT CARS AGAINST RUST!

?Dream on? They warrant against rust "perforation" which is

really only the last stage of the entire rust process. By

the time rust perforates, the damage is fairly severe.

IF A CAR RUSTS, IT CAN BE EASILY REPAIRED:

More wishful thinking. Rust repair is like tooth decay -all

the bad metal must be excised and new metal inserted and

shaped. Not only is this very labor intensive, but the heat

used to weld the new metal makes the repair more vulnerable

to future rusting. Talk about a Catch--22! Most body shops

in these areas will give no warranty on rust work, while

some will offer a 1--year warranty if the owner insists.

The situation is made worse by the fact that many owners

decide to paint their older vehicles just prior to sale to

"mask" existing rust. Logic tells us that the quality of the

body job they select in this case would likely be the

cheapest and the fastest. And logic would be right!

HOW TO KEEP RUST FROM STARTING

The key to keeping a rust--free car is by stopping rust

before it can start. Or at at least address it before it

eats its way through to the other side. Because bare metal

will oxidize and painted surfaces won't, you only need to

protect your car from the elements to keep rust at bay. You

should maintain your car's body just like everything else.

This means a periodic checking of the most common areas

where rust might rear its ugly head.

Keep some touch--up paint on hand and periodically go over

your entire cars painted exterior with fine toothcomb. Look

for chips and nicks in the paint. If you find a chip where

surface rust has already weaseled its way in, use sand paper

(220 grade or finer) and carefully sand it down to bare

metal. Tiny nicks will be a challenge. Wrap the sand paper

around the tip of a small screwdriver and try not to mar the

surrounding painted surface.

Clean the dirt from the chips with a rag dampened with

mineral spirits and let dry. Using a touch--up brush, dab a

little paint on the nick, just enough to fill in the gap.

There's no need to coat the surrounding painted surface.

Otherwise it will just make your touch up more noticeable.

Do it right and your nick practically becomes invisible. If

you botch up your first try just wiping it off with your

dampened rag, let dry, and start over.

Periodical washing of your car's undercarriage is also a

good way to protect your car from corrosion. Spray the

underside of your car and inside the wheel wells too. A

build up of dirt @ sand can hold moisture against your car's

undercarriage and promote rust. Keeping it clean under there

will allow surfaces to dry quicker making it less

susceptible to oxidation.

It's also a good idea to inspect the underbody as well for

loose undercoating as the factory stuff has been on there

for over thirty years. Touch up any broken of bits and touch

up chipped floor boards with anti rust paint and the

re--touch the affected area with undercoating.

Rust Removal Methods

Lets see now, we have a few unheard of options from the

garage to Granny's Kitchen and a few trips to the laundry

room to boot.

Electrolysis, vinegar, Coke, molasses, muriatic acid,

sanding, wire brushing, grinding, sand blasting etc...

So we are into an all out war against rust, it is the

eternal enemy and finding effective ways to eradicate the

evil annoyance is the Holy Grail of this crusade.

So read on as I continue this confrontation head on into the

battle lines with rusty.

Most of the methods require some common sense and caution.

|

| |

|

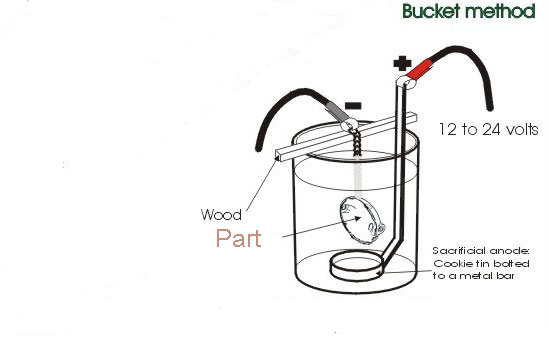

Electrolysis |

Electrolysis

What is Electrolysis you ask?

Well Electrolysis is a method of removing hair permanently,

Sorry just kidding lol Or is it?

Electrolysis refers to the production of an

oxidation--reduction reaction

by means of a direct current.

It means that an electrical current (DC) can be applied to a

system in

order to force a reaction to occur. In this reaction, there

is an

oxidation of one species, and a reduction of another. Think

of it as

a battery operating in reverse.

Electrolysis

Basically, what we have here is a cheap, easy way to clean

off rust, and actually in some cases, paint, from our little

parts

What you need:

1. A large non--conductive container that will hold the

part in water - A Rubbermaid tub, a plastic bucket, or a

large non--metal trash can all work great as long as they

don't leak. Or for large projects a cardboard or wooden

form to be lined with plastic.

2. A

battery 6--10amp charger or other source of 12V DC power.

4.

Sacrificial electrodes - iron re--bar works great or a steel

plate, stainless steel is very bad (and the result is

illegal and dangerous).

5. Arm & Hammer Laundry Soda, also known as washing

soda.

6. Some

chains or steel wire to suspend the part in the solution -

copper wire is bad and messy.

7. Water

The basics are pretty simple.

1. Find a container big enough to hold your part, plus some

room to spare for the electrodes - they must not touch the

part for this to work.

2. Fill the container with water and add 1/3 to 1/2 cup

laundry soda per every 5 gallons of water. Mix thoroughly

3. Position the sacrificial electrodes around the edge of

the container and clamp them in place so that you have at

least 4" of electrode above the water to connect to. The

more the merrier - this is essentially a "line of sight"

process between the part and the electrodes.

4. Wire all of the electrodes together so they are,

electrically speaking, one big electrode. Make sure all

connections are on clean metal and sufficiently tight to

work

5. Suspend your part in the solution using the wire/chains

so it is not touching the bottom and is not touching any

electrodes. The part must be electrically connected to the

support mechanism and not connected to the electrodes for

this to work.

6. Attach the battery charger NEGATIVE lead to the part and

the POSITIVE lead to the electrodes. Do not get this

backwards! If you do, you'll use metal from your part to

de--rust your electrodes instead of the other way around

-the positive electrodes are sacrificial and will erode over

time. That's how the water becomes iron--rich.

7. Double check everything to be sure the right things are

touching, the wrong things are not touching, and the cables

are hooked up correctly.

8. Turn on the power - plug in the charger and turn it on.

Within seconds you should see a large volume of tiny bubbles

in the solution - these bubbles are oxygen and hydrogen

(very flammable!). The rust and gunk will bubble up to the

top and form a gunky layer there. More gunk will form on the

electrodes - after some amount of use, they will need to be

cleaned and/or replaced - the electrodes give up metal over

time. That's why re--bar is such a nice choice - it's cheap

and easy to get in pre--cut lengths.

The process is self--halting - when there is no more rust to

remove, the reaction stops. This is handy because you don't

have to monitor it, and because you can do large parts where

they are not totally submersed at one time without worrying

about "lines" in the final part.

Once you are done, the part should immediately be final

cleaned and painted - the part is very susceptible to

surface rust after being removed from the solution. There

will be a fine layer of black on the part that can be easily

removed, and once it is removed, the part can be

primed/painted as needed. Safety Precautions

You're playing with serious stuff here, so stay safe. It's

not rocket science, but if you're new to this, you might not

know all of this - so read up before you do any of this.

This process produces highly flammable and explosive

hydrogen gas (remember the Hindenburg?), so do it outside,

or in some other well ventilated area. Hydrogen is lighter

than air (like natural gas), so it will collect near the

ceiling - not sink to the floor like some other flammable

vapors will (like propane and gasoline). If you have open

flames near this (Hint: gas appliances like water heaters

and furnaces have pilot lights!) you will most likely

severely injure or kill yourself (and others near you) and

become a contender for the Darwin Awards in the process.

? Assuming you used re--bar and steel wire/chain like you

were told to, the waste water resulting from this is

iron--rich - it's perfectly safe to pour it out onto the

grass and your lawn will love it. Beware of ornamental

shrubs that don't like iron--rich soil though, unless you

like making your wife mad at you.

? Make sure the battery charger (or whatever source of power

you use) stays dry. All of the usual cautions about any

electrical device in a wet environment apply here.

? The solution is electrically "live" - it is a conductor in

this system. Turn off the power before making adjustments or

sticking your hands into the solution. You can get a mild

shock if you stick your hands into the water with the power

on.

? The solution is fairly alkaline and will irritate your

skin and eyes. Use gloves and eye protection. Immediately

wash off any part of your body the solution comes into

contact with with plenty of fresh water.

? Don't use stainless steel for the electrodes. The results

are toxic and illegal to dump out.

? Don't use copper for the electrodes and anything else in

the water - the results are messy.

If you are unsure of any of

this or unsure about your safety - STOP! Get help before you

do something stupid. Use common sense, be smart about what

you're doing, and stay safe so you can finish your

restoration project and enjoy it.

Why you

should not use stainless steel electrodes for electrolysis

Many people using the electrolysis method for rust reduction

swear by stainless steel, stating (incorrectly) that it's

not consumed, stays clean and seems safe.

Stainless steel is indeed consumed when used in the

electrolysis process, although slowly. The main problem with

using it is the hazardous waste it produces. Stainless steel

contains chromium. The electrodes, and thus the chromium is

consumed, and you end up with poisonous chromates in your

electrolyte. Dumping these on the ground or down the drain

is illegal. The compounds can cause severe skin problems and

ultimately, cancer. Hexavalent chromate is poisonous. These

compounds are not excused from hazardous waste regulations

where household wastes are.

These compounds are bad enough that government regulations

mandate "elimination of hexavalent chromate by 2007 for

corrosion protection."

Does your electrolyte turn yellow? That's a sign of

chromates.

If you have been using stainless steel for the anodes

(positive electrodes), wear rubber gloves when working with

or near the liquids. If you need to dispose of it, allow it

to evaporate into powders and dispose of the powders in

sealed containers during your local "hazardous waste

clean--up days".

Best bet - don't use stainless steel no matter how tempting

it is.

|

| |

|

Molasses |

Sounds nuts, well I

thought so too, From the scary to the insane!

Well you have got to see this.

Materials required are two slices of bread well toasted one

side only please, a good thick slightly warmed up paste on

one side of the toast then smear away at the rusted body

panel.

Well, hell mine sounds just as crazy but not really when you

read and see the results.

Very important part about the Molasses part, Make sure you

buy the Molasses that doesn't say "Sulfur Free"

It works real well. Will not remove paint, but removes rust.

Mix about 5 parts water to 1 part molasses and submerge your

part for about 2 weeks. You can use a bucket, a kids size

swimming pool, or anything else big enough to hold your

parts.

If you want to experiment with this, try a small sample in a

coffee can or something. Get a bottle of molasses at the

grocery store, mix with water in an ice cream bucket. Find a

small, real rusty piece of sheet metal to experiment with.

It'd be best to suspend it in the can from a wire so all

parts get evenly soaked. Resist pulling it out everyday to

look at it. Pull it out in a couple weeks and hose it off.

You might want to keep the bucket outside, though, as it

will smell

Here is a story I found on a blog about this method

I had a tip a while back about rust removal...put it in a

molasses and water mixture, and VOILA, no rust. I didn't

believe it. Well, somebody I really respect finally

recommended it to me, for a stubborn rust problem, and I

tried it. He recommended mixing 1 part molasses to 12 parts

water. I also heard 1 LB molasses to gallon of water, and

1:20 ratio, although weight or volume was not specified. I

used my calibrated eyeball to mix up the solution, and put a

very rusty WWII tail light door, a cast iron oil pump with

nickel plating, and a forged steel piece in the same bath,

and watched it every day. The first day, most of the rust on

the tail light door was GONE! The casting was losing rust,

and the forging had noticeable reduction of rust. It

continued to improve each day. After two weeks, the tail

light is almost whistle clean. The casting is the same, and

the plating was not touched. The forging is still resistant,

and has a little left in the shallow cast pits on the

surface. All of the painted surfaces are untouched. I am

really amazed by the progress. I don't know what the process

is, and don't know how it will continue to work, but $2.29

of Grandma's Molasses and .00001 cents of Baltimore City Tap

Water are really doing a better job than a glass beader.

Tomorrow, I am going to the feed store, to buy 50 Lbs of

Feed grade Molasses for $18.54, and am looking forward to

saving on the sand blasting bill this spring (Oh boy, an

ambulance, an MB, a carryall, and a motorcycle- any little

bit helps) Has anybody else used this technique? Any tips on

technique, other than pour, wait, and wash?

And they laughed at me when I told them about it twelve

months ago, if you really want to know what causes it,

Phosphoric Acid, (excuse the spelling), is created in the

mix, a better solution is 10:1 ratio. The mix will lose it

strength after awhile (about 8--12 months), but it's good

value for money.

Now are you hyped up, ok here is the pudding in the proof.

|

| |

|

Coke |

Rust Removal Using - Soda Pop?

I am sure you have all heard this one before but has anyone

tried it?

many carbonated beverages will remove rust. This is because

the gas used, carbon dioxide when mixed with water, makes

carbonic acid. To make rust, the iron oxidizes - it combines

with oxygen. This is why rust is also called iron oxide. The

carbonic acid reverses this reaction - this reversal is

called "reduction." Here's a better reason - take a look at

your Coke can - it has phosphoric acid as an ingredient.

Phosphoric acid is the basis of Naval Jelly, a commercial

product used for rust removal. Phosphoric acid dissolves

iron oxide very quickly while etching metallic iron very

slowly so you can leave metal in phosphoric acid with little

damage.

The downside is that all acids contribute some hydrogen to

the metal structure, weakening the steel by hydrogen

embrittlement - so always use only as much time as is

absolutely necessary to remove the rust. An advantage of

phosphoric acid is that it leaves a fine protective coating

of iron phosphate. Because this coating is not thick or

durable some protection is still required. Years ago

supposedly Volkswagen use a process of phosphating metal

prior to painting as it provided a chemical protection

against rust under the paint layer.

So, spilling your Coke into your old engine wouldn't really

be a bad thing if you were trying to remove some rust. |

| |

|

Ultra One |

Here is a product

that I think is amazing and seems to be non--toxi.

Take the time to read through the before and after, the

results are impressive and very quick too.

Ultra One Corporation

Edgewater Industrial Park

112 East Ave., Unit 8

Hackettstown, NJ 07840

Tel: 908--684--5444

Fax: 908--684--5455 |

| |

|

|

|

|

|

|

|

|

|

|