|

|

|

|

|

|

Vulcan's Grot Watch |

|

|

Welcome to Vulcanís Body shop!

Vulcan (vul-kan): That lad what made bits of stuff fer tíRoman

gods; a large, extinct delta-winged bomber; them sorts what have sex

every seven years.

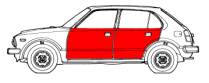

Got rust? Just hover your pointer over the piece of

bodywork

youíre interested in and click to get to that page. Iíve

tried to provide Ďbeforeí and Ďafterí pictures but sometimes

when I get the urge to work, I just donít get time! BTW, this bit only

includes how to spot the grot, for fixing it just follow the links. I

intended these pages to be a useful bit if youíre looking to acquire

one of these cars, or just want a guide to where the metal moth is

likely to attack. Donít want you getting stung do we?

Also, click on "What the frig?!"

for details of rust & that you wonít see until youíre stripping

the car down or you find it accidentally. Like just when you think youíre

finished with that bitÖÖ...

Aye-up Toto! Weíre ainít in bloody Kansas any more! For all you

newbies to bodywork or cars in general then this

bitís for you. Here Iíve put in details of tools,

techniques and some rules of thumb to help you on your way.

For those of you with a little more experience Iíve also included

notes on how to do what I did so hopefully youíll get better results.

Please note that none of this info is necessarily the best way of doing

something. Iíve provided info on what Iíve done and has worked, so

feel free to Ďdo your own thingí (I know I did!)

Anyway, without further ado, hereís the bit youíve

been waiting for.

|

|

|

|

|

|

Doors

|

Rear

Valance

|

Rear

Hatch

|

|

|

|

|

Rear

Wheel Arches

|

A-Posts

& Scuttle

|

Bumper

Blades

|

|

|

|

|

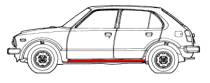

Sills

|

Hood

|

Front

Valance

|

|

|

|

|

|

Boot

Floor

|

|

|

Wings

|

Boot Floor

|

|

|

Wings

Okay, hereís how to tell if you need a new wing or not. This is also

quite helpful if youíre buying one of these. These symptoms can be used

as leverage if youíre trying to bring the price down. First Iíll tell

you what to look for with the wing on and then what to look for if you

have it off. (And donít say Dannii Minogue!!!!!)

Rust on the outer wings is easy to spot. Starting from the front look

for signs of paint bubbling or flaking around the lower two bolts holding

the wing to the front valance. Feel the texture of the metal. Itís quite

thin around this point and any Ďgiveí in the metal will mean advanced

corrosion. Expect the valance to be corroded as well.

Next examine the indicators. These are held on by self-tapping screws

secured through small metal clips that slip onto the panel. Corrosion

directly at the ends of the indicator is usually due to these clips

chafing the paint away. Unless youíre very unlucky only the surface of

the panel should be affected.

|

|

Corrosion forming between the top of the indicator and the

hood is more serious. This is probably due to perforation of the

panel from underneath. The front bulkhead butts against the wing

at this point and is separated by a rubber strip. Corrosion here

is usually because the rubber has chafed the wing from underneath,

allowing water in. This usually means that the bulkhead is

buggered as well and should be checked. A quick inspection can be

made by removing the trim surrounding the headlamp. If rust can be

seen on the top left of the bulkhead then expect to make repairs.

In the UK this panel is often bodged. If you can see metal patches

pigeon-shitted on then expect advanced corrosion to be present

when the wing is removed.

Signs of corrosion along the top of the wing is serious. This

means that the flange bolted under the hood is likely to be as

rotten as a pear and is about ready to part company with the

panel. Feel it. If it crunches then youíve got trouble. While

youíve got the hood open any bodgery around the tops of the

inner wings will be easy to spot. If in doubt, remove some of the

wing retaining bolts. They should be 10mm Isometrics fixing into

captive nuts under the inner wing. If theyíre self-tappers then

the inner wingís been stuffed up big time. Expect to break out

the MIG Signs of corrosion along the top of the wing is serious. This

means that the flange bolted under the hood is likely to be as

rotten as a pear and is about ready to part company with the

panel. Feel it. If it crunches then youíve got trouble. While

youíve got the hood open any bodgery around the tops of the

inner wings will be easy to spot. If in doubt, remove some of the

wing retaining bolts. They should be 10mm Isometrics fixing into

captive nuts under the inner wing. If theyíre self-tappers then

the inner wingís been stuffed up big time. Expect to break out

the MIG

|

Now

examine the trailing edge of the wing. A vertical line of

corrosion is serious. The wing comprises two main panels, the

smaller of which is secured to the outer panel by a fold of

steel. Corrosion normally means the two are trying to part

company. Expect the small tab at the bottom, bolting the wing to

the sill, to be rusted as well. (If it is then removal of the

wing will probably reveal surface corrosion on the inside of the

panel above it. Now

examine the trailing edge of the wing. A vertical line of

corrosion is serious. The wing comprises two main panels, the

smaller of which is secured to the outer panel by a fold of

steel. Corrosion normally means the two are trying to part

company. Expect the small tab at the bottom, bolting the wing to

the sill, to be rusted as well. (If it is then removal of the

wing will probably reveal surface corrosion on the inside of the

panel above it.

|

Okay, now letís have the wing

off. There are eight bolts in total. Four along the top under

the hood, two on the front valance, one at the base of the

A-post and one behind the headlamp trim. Okay, now letís have the wing

off. There are eight bolts in total. Four along the top under

the hood, two on the front valance, one at the base of the

A-post and one behind the headlamp trim.

Youíll be faced with something like this. Donít be

surprised if you see a shorter version. Some didnít extend

past the suspension turret I believe.

|

|

This is what it should look like underneath all of that filth.

This is what it should look like underneath all of that filth.

A missing piece of bodywork is an obvious indication that

the body has been seriously butchered but weíll take this from

the top. N.B. If you have shortened chassis rails they will be

tapered in against the inner wing. There should be no open ends. A missing piece of bodywork is an obvious indication that

the body has been seriously butchered but weíll take this from

the top. N.B. If you have shortened chassis rails they will be

tapered in against the inner wing. There should be no open ends.

.

A

missing piece of bodywork is an obvious indication that the body

has been seriously butchered but weíll take this from the top.

N.B. If you have shortened chassis rails they will be tapered in

against the inner wing. There should be no open

ends. A

missing piece of bodywork is an obvious indication that the body

has been seriously butchered but weíll take this from the top.

N.B. If you have shortened chassis rails they will be tapered in

against the inner wing. There should be no open

ends.

|

|

If

you already know from the above instructions that the top of the

inner wing has been bodged start the examination at the back,

from where the upper chassis rail is welded against the A-post.

Any corrosion of the top of the inner wing or the scuttle in

front of the windshield in this area is indicative of serious

problems. The flange on the top of the inner wing, the wing

itself and the chassis rail form a 3-sided box section that

traps mud and moisture kicked up by the wheels. If this has

collected sufficiently to rot the flange than the chassis rail

will almost certainly have been perforated. Look for surface

corrosion first. However, if the car has received the

ministrations of a cheap body-shop it may be covered by lashings

of cheap under seal. The best way to check is to squeeze it. Any

give along the top of the chassis rail means itís scrap. If

you already know from the above instructions that the top of the

inner wing has been bodged start the examination at the back,

from where the upper chassis rail is welded against the A-post.

Any corrosion of the top of the inner wing or the scuttle in

front of the windshield in this area is indicative of serious

problems. The flange on the top of the inner wing, the wing

itself and the chassis rail form a 3-sided box section that

traps mud and moisture kicked up by the wheels. If this has

collected sufficiently to rot the flange than the chassis rail

will almost certainly have been perforated. Look for surface

corrosion first. However, if the car has received the

ministrations of a cheap body-shop it may be covered by lashings

of cheap under seal. The best way to check is to squeeze it. Any

give along the top of the chassis rail means itís scrap.

If the section between it and the scuttle appears solid

though, thoroughly clean the area with wire wheels

and a

3M Scotch

Brite disk. This one had been prettied up with body filler, bits

of scrap Dexion and the obligatory cheap under seal. If this

section of the chassis rail is as bad as this then I donít

reckon itís safe to leave any of it on the car. Take the whole

lot off and start with a clean slate. I used an angle grinder

and

a cold chisel to take the top layer of metal off the spot welds.

|

|

Moving

down, check the metal by the suspension turret. If youíve

already taken the chassis rail off then this bitís easier to do.

Thereís a line of spot welds where the suspension top plate is

welded to the inner wing. Any bodgery of the flange above the

turret is cause for immediate concern and my advice would be if

yours has been buggered about with then you should consider, if

you havenít already, removing all or part of the chassis rail. Moving

down, check the metal by the suspension turret. If youíve

already taken the chassis rail off then this bitís easier to do.

Thereís a line of spot welds where the suspension top plate is

welded to the inner wing. Any bodgery of the flange above the

turret is cause for immediate concern and my advice would be if

yours has been buggered about with then you should consider, if

you havenít already, removing all or part of the chassis rail.

You canít inspect the welds with it

in-situ. If these welds

are compromised then it would seriously weaken the top plate, in

fact rust may already be beginning itís journey up and over it.

I got to mine just in time. There was about 4mm of steel left

before the welds.

Now

letís look at the front bulkhead. If, as described above, youíve

already taken the headlamp trim off and seen what looks to be a

spray-painted Ryvita attached to your car then your bulkhead needs

work, and the front of the chassis rail will probably be shot too.

Again, look carefully for signs of well-concealed bodgery. Check

the front scuttle as well. Now

letís look at the front bulkhead. If, as described above, youíve

already taken the headlamp trim off and seen what looks to be a

spray-painted Ryvita attached to your car then your bulkhead needs

work, and the front of the chassis rail will probably be shot too.

Again, look carefully for signs of well-concealed bodgery. Check

the front scuttle as well.

|

|

Just one

more thought I want to leave you with. Donít assume that because

it feels solid then itís okay. This bit looked fine on

the outside. In fact, it was almost a shame to remove it but

because I was already pulling

the outside. In fact, it was almost a shame to remove it but

because I was already pulling

off the chassis rail, it had to go. I ripped it off and took a

look at its obverse side. Rotten as a pear. The lower half was the

only bit that was original, the top was made of scrap angled steel

held on with tacks. This was bodgery at its worst and the under

seal and filth did a good job of hiding it. You canít be too

careful.

off the chassis rail, it had to go. I ripped it off and took a

look at its obverse side. Rotten as a pear. The lower half was the

only bit that was original, the top was made of scrap angled steel

held on with tacks. This was bodgery at its worst and the under

seal and filth did a good job of hiding it. You canít be too

careful.

Okay, youíve

read the above after youíve bought the car and found the inner

and outer wings, front valance and the upper chassis rail are

shot. Firstly, swear. Thereís a lot of metalwork that needs to

be done. Secondly, check out the ĎTools

of the Tradeí, Iíve made some recommendations of what youíll

need to buy. Thirdly, have a look at this next bit.

|

|

HELP

ME NUH!!!!!!!

|

Boot Floor

What the frig?! Verily. Thatís putting it mildly when I discovered this little batch of loveliness in the boot floor! My real language near turned the air blue so I doubt

anyone would much appreciate me putting it on the site! The meaningís the same though. You think that bitís looking all pukka then you have a bit of a

ferret about for no good reason, just a strange sense of unease, the sort you might get after eating too much chocolate. (Assuming itís possible to do such a thing!)

Okay, this is what you might be confronted with: ĎOrrible ainít it? I saw a little Ďsurfaceí corrosion on the boot floor on the underside. Looked in the boot and it looked fine. Then I

realized that there was a bunch more metal hiding behind the trim panel. Took that out and initially it didnít look too bad. There was a lot of sealer round the joins which hid most of it. The wire wheel though didnít just remove the sealer it also knocked out a great lump of boot floor. A bit more poking with a screwdriver revealed even more fresh air. You canít be too careful.

After Iíd used the nibbler and senior hacksaw blade to cut out the rot this was what was left. Not nice.

|

|

This is how it looked when Iíd finished, namely, what itís supposed to be looking something like.

As you can see, itís just tacked in place for the moment but itíll be seam welded later. This is the kind of repair thatíll make you a bit depressed. After taking the trouble to make the indented section for the grommet and making a panel to butt-weld into the boot floor youíve got to come to terms with the fact that your handiwork will never again see the light of day. At least youíll know itís there though instead of a fistful of rust, which is the main thing.

|

|

Tools of The Trade

|

|

Okay,

hints and tips time for newbieís and the confused. First off,

donít worry! We all have to start somewhere. I started my

restoration when the fog light lens fell off the car. Iíd had

it in storage for a few years wondering where to begin and then

one day, plop. It kind of snowballed from there!

First

rule is:

Donít

take it apart unless you know how it goes back together! How

many times have we seen or heard of this? Someone taken on a

project, often quite reasonable, and then gets rid of it because

they have made a pigís ear of it? (Or run out of money!) If

youíre new to the game then what Iíd suggest is that you

invest in a digital camera. It doesnít have to be fancy, just

good enough to take clear pictures when needed. Donít launch

yourself into a total strip down if this is your first time out.

Firstly, you might lose valuable parts & re-assembly info,

and secondly you could end up sitting in a garage surrounded by

boxes of dirty parts, crying into your tea and muttering ďOh

god, oh godÖ..Ē at the thought of the monumental task ahead.

Remember: Baby steps!

Second

rule is:

Buy

good tools! Donít

go down to your local Pound land and buy the biggest

presentation-boxed-socket-set you can find. You will get a load

of bits youíll probably never need and no room in the case for

extra ones you do. Not to mention the overall quality of the

tools might not stand the test of time and frustrated humans!

Get what you need when you need it and go for quality, the best

you can afford. I quite fancy Metrinch sockets and spanners, but

to save money Iíll go for cheaper unbranded ratchets and tommy

bars. These are quite good because theyíll still work even if

the head of a nut or bolt has rounded off a bit after having at

it with a cheaper socket! Cheaper sockets do have their place

but Iíll say more on the link above.

Third

rule is:

Take

your time! Weíll all hit ĎThe Wallí from time to time, so

if things arenít going to well, just put your tools down and

come back to it later. Sometimes youíre Ďin the zoneí and

other days you arenít. By the same token though if things are

going too well, just ask yourself ďam I doing this right?Ē

Iíve had that a few times. You think youíve just make a

cracking pair of wheel arches (or whatever) and then you realize

youíve made them for the same side. Yes, dumb mistake I know

but not very serious though. When it comes to cutting rotten

metal out of your car though, things can get very serious, if

not unsafe. I have heard stories about people launching

themselves into a restoration, cutting the sills out of their

newly acquired Consul Capri and welding in new ones, only to

discover that the doors no longer fit. By cutting out both

sills, they had allowed the car to flex. Remember what I said

about unfinished projects? Yep, it does happen.

Fourth

(and final) rule is:

Be

inventive! With

these cars thereís bugger all available so youíll have to be

a bit clever when it comes to replacing the irreplaceable! It

can be done though. Click on this link and youíll find all of

the little dodges that Iíve used. I would suggest that you

check out the other stuff above before going here, that way at

least youíll know what Iím going on about.

Right,

that is your initial grounding in the ways of Civic restoration.

This is what I have learnt through practical hands-on

experience. Iím not trained in anything so what Iím telling

you is what Iíve taught myself, therefore there shouldnít be

anything here you wonít find a use for, especially if this is

your first time out. Enjoy!

|

|

Wheel

Arches

Okay. Letís begin at the beginning, which in this case is at the ass-end. Have a shufty at the ends of the valance, where the

wheel arch folds over it. You should see something like this. Nice and even. Thereís no

mud flaps on this motor so you can see the steel nice and clear.

If youíve got mud flaps then look for ones that donít fit well. Thatís usually a sign that the steel behind has been patched up with dexion plates and wag. Hereís a picture of my motor, itís not finished but thatís what youíre looking for. A straight, snug-fitting flap. If yours looks a bit peculiar then the chances are it was either fitted by a visually-challenged

dysphasic chimp, or more likely thereís some bodgery under it.

Be on the look out for this too. Splits in the bodywork are a sure sign youíve got rot and filler. Plain, unmolested steel shouldnít split like that in the middle of a panel. Blistering paint means the panelís rusting from the underside. I really wish Iíd got more

picturess of this panel when I was stripping it down. This was a prime example of how not to Ďfixí a car. Be on the look out for this too. Splits in the bodywork are a sure sign youíve got rot and filler. Plain, unmolested steel shouldnít split like that in the middle of a panel. Blistering paint means the panelís rusting from the underside. I really wish Iíd got more

picturess of this panel when I was stripping it down. This was a prime example of how not to Ďfixí a car.

As it happens this bit of twattery was proudly provided by V&J Autospray in Kenilorth. It was run by this aged retard who drove round in a Mk1 Cortina, who had the temerity to proclaim once, in my presence no less!!!!!!!! That: ďWhen a car gets to a certain age thereís not a lot you can do with it.Ē Hmm........ I wonder if he had the intellect to actually spell hypocrisy. As it goes he retired and gave the business to his shit-stain daughter. She once spent half an hour trying to convince my mother that she: ďCould get two and a half grand for it in that condition, in that condition itís worth two and a half grand, and if you were to sell it youíd get two and a half grand for it. In that condition, two and a half grand would be the price for it if you were to sell it for two and a half grand....... etc......Ē As it happens this bit of twattery was proudly provided by V&J Autospray in Kenilorth. It was run by this aged retard who drove round in a Mk1 Cortina, who had the temerity to proclaim once, in my presence no less!!!!!!!! That: ďWhen a car gets to a certain age thereís not a lot you can do with it.Ē Hmm........ I wonder if he had the intellect to actually spell hypocrisy. As it goes he retired and gave the business to his shit-stain daughter. She once spent half an hour trying to convince my mother that she: ďCould get two and a half grand for it in that condition, in that condition itís worth two and a half grand, and if you were to sell it youíd get two and a half grand for it. In that condition, two and a half grand would be the price for it if you were to sell it for two and a half grand....... etc......Ē

But I digress. Underneath all of that cheap paint and pudding was this. Fresh air anyone? Not good, not good at all. My advice here would be grab the back of the

wheel arch and give it a good squeeze. Any give or crunching sounds and Iíd say steer well clear, or use it as leverage to bring the price down to a realistic level, say about £2.50! Donít forget Ė you canít get the repair panels for these cars, not at all so donít get yourself lumbered with a real basket case unless youíre sure you can fix it. Bondo and chicken wire just ainít good enough people! With that in mind you should be able to spot a basket case real easy as your typical grease-monkey from Verruca & Jerkoff Autospray wouldnít be able to follow a compound curve to save his miserable life.

Now then, now then, as Jimmy Saville used to say. Letís press on. The next way you can tell if youíre looking at a lemon is only really applicable to 4 & 5 door cars and Wagons. Thatís to open the door and take a good long look at the door shuts. Compare these

pictures.

Spot the difference? I thought you might. See on the right pic thereís an indentation in the door shut to

accommodate the rubber door seal. On the left is a pic of mine. As you can see V & J Twatspray have filled it full of pudding. If you look real close you can see a faint line in the paintwork, caused by the door rubber chafing itís way through the crap. Result? The door donít fit. Youíd have to slam it right hard to make it close. As it goes the rear wheel arches were the only bits of monocoque body that had aftermarket patch bits available. Needless to say they were crap, but they were only ever available for 3-door cars. When this sort of mess is dug out what youíll find is likely to be a 3-door arch thatís been tacked to the car at the back and the front bit has been hammered (literally) into the recess. Bloody

wankshafts. Spot the difference? I thought you might. See on the right pic thereís an indentation in the door shut to

accommodate the rubber door seal. On the left is a pic of mine. As you can see V & J Twatspray have filled it full of pudding. If you look real close you can see a faint line in the paintwork, caused by the door rubber chafing itís way through the crap. Result? The door donít fit. Youíd have to slam it right hard to make it close. As it goes the rear wheel arches were the only bits of monocoque body that had aftermarket patch bits available. Needless to say they were crap, but they were only ever available for 3-door cars. When this sort of mess is dug out what youíll find is likely to be a 3-door arch thatís been tacked to the car at the back and the front bit has been hammered (literally) into the recess. Bloody

wankshafts.

But donít just take my word for it folks, res ipsa locutor as we say in the law! Bodgery = Fresh air. Simple as that. By the time the recess in the door has disappeared under pudding, you can almost guarantee that the original arch, or any useable bit of it, has been claimed by the metal moth. Again, unless you know how to fix it properly Ė steer clear.

|

|

Sills

Okay, letís assume youíre looking at the car for the first time, whatís going to set the alarm bells ringing? Patches, lumps of MIG and/ or a sticky coat of fresh

under seal apply here, as with any other car but also look for a smooth, curved profile to the sill. If you see this as opposed to gentle swaging along its length then the car youíre looking at has been bodged big time. Itís not easy if youíre unfamiliar with Civics to tell if the sills youíre looking at are shot or not so hereís some

pictures. What youíre looking for is this:

In particular itís the shadow being highlighted by that fetching green arrow. Thatís the underside of a broad swage that runs along the top of the exposed area of the sill. Although itís only the most delicate of details it is still clearly defined. If it isnít (or if itís missing) then the sill had been buggered with. Here it is in profile: In particular itís the shadow being highlighted by that fetching green arrow. Thatís the underside of a broad swage that runs along the top of the exposed area of the sill. Although itís only the most delicate of details it is still clearly defined. If it isnít (or if itís missing) then the sill had been buggered with. Here it is in profile:

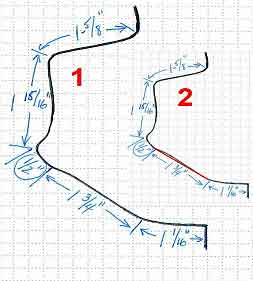

Picture 1 shows you how the profile should be, picture 2 is what youíll see if someoneís been sodding about with it. Notice the red line on 2. Thatís where the outer surface is likely to be after welding/ filling. Itís only a small difference but itís a real giveaway. If you canít even see the swage below it easily then youíve got repeated patching or cover sills but weíll say more about that later. Picture 1 shows you how the profile should be, picture 2 is what youíll see if someoneís been sodding about with it. Notice the red line on 2. Thatís where the outer surface is likely to be after welding/ filling. Itís only a small difference but itís a real giveaway. If you canít even see the swage below it easily then youíve got repeated patching or cover sills but weíll say more about that later.

Letís assume for a moment that the sill has been Ďdoctoredí. If youíre not a competent tinsmith then walk away. Thatíll need digging out and probably at least the lower 1/3 of the sill replacing, more at the back. If the sill looks good then to be absolutely certain itís as good as it looks then grab the back end of the sill and squeeze real hard. If thereís any sounds of cracking, any give or if your fingers go through then be prepared for trouble.

As a matter of interest, if the sills are smegged then if you can remove the front wings this is what youíll probably see: As a matter of interest, if the sills are smegged then if you can remove the front wings this is what youíll probably see:

Lurvely!!!! Just compare it to the picture at the top of this chapter. Doesnít look like the same kind of car does it? Interesting points to note is the complete lack of profile/ character on the sill. Itís just been turned into a

homogenized blobby curve by repeated patching. Remember above I mentioned cover sills? Well, note the area just in front of the bottom corner of that door there. You can just see a panel curving up over the top of the upper sill swage. Thatís a cover sill. As it goes this one was nicely Ďsmooved iní along the top with pudding. Done by some some twunt down Red Lane in Coventry years back. Heís ceased trading ages ago so I canít go down there and beat the shite out of him with my grandfatherís ball-pien hammer. Worse luck..........

Okay, letís assume from hereon in that your car has a cover sill. Getting it off is the easy part. Cover sills will 99% of the time have been fitted by a blind badger in a furry anorak. Dig out the kitty hair/ chewing gum/ polyfilla along the top of the sill and 10-1 youíll see vague line of tacks securing the patch to the car. Have at these with an angle grinder and separate it from the car initially with a cold chisel. All you want to do is break the final bonds between it and the precious car. Then itís a simple as leaning down on it. Really! Itís that easy! The patch should simply fold down out of the way. Fold it up and down a few times and thanks to the phenomenon of metal fatigue it should just break away. An interesting note here would be to say that mine didnít do this. When I leaned down on it the front 2/3 of the patch simply broke away from the car. The back end was attached only by a thin scrap of a rusty patch which gave way when I stabbed at it with a crow bar........ about a dozen times..............

Hereís a picture of the sill after the cover was removed. I didnít get one before it was taken off (sorry!) As you can see, thereís a dashed line of dark patches on the paint. Thatís where the pigeon-shit (itís a valid welding expression!) line of tacks had burned the paint. Also you can see that the back of the sill is almost totally eaten away. As it goes Iíve chosen to reconstruct the sill before I tackle the outer skin of the wheelarch. The problem is that so much original datum information has been lost over the years. Thatís why Iíve elected to extrapolate/ extend from the original steel that I still have left, hence why Iíve elected to reconstruct the sills before finishing the outer skin of the

wheelarches. Hereís a picture of the sill after the cover was removed. I didnít get one before it was taken off (sorry!) As you can see, thereís a dashed line of dark patches on the paint. Thatís where the pigeon-shit (itís a valid welding expression!) line of tacks had burned the paint. Also you can see that the back of the sill is almost totally eaten away. As it goes Iíve chosen to reconstruct the sill before I tackle the outer skin of the wheelarch. The problem is that so much original datum information has been lost over the years. Thatís why Iíve elected to extrapolate/ extend from the original steel that I still have left, hence why Iíve elected to reconstruct the sills before finishing the outer skin of the

wheelarches.

Hereís the cover sill after removal. Just for the record thereís a large chunk missing from the back of it. It should have extended along the length of the patch that you can see just sticking out to the left there. Hereís the cover sill after removal. Just for the record thereís a large chunk missing from the back of it. It should have extended along the length of the patch that you can see just sticking out to the left there.

You can clearly see also where the cover sill itself has been patched. Badly. The twunts responsible for this are still trading. While on the one hand Iím tempted to go round there with a crate of petrol-filled brown-ale bottles Iím not actually too fussed. Itís only a cheap cover-sill theyíve mullahed after all. As the guy from ĎChristineí said ďYou canít polish a turdĒ. In any event, it was my mother that was actually fool enough to pay them........

Along the bottom edge of it you can also make out a line of Ďblobsí. Theyíre not just any old blobs. Theyíre the remains of plug welds. Thatís where the upper panel of two pieces being lapped has holes made in it which are then subsequently MIG welded round inside their circumference. As a matter of interest when this sill was taken off and examined from the rear:

I actually found that they had been trying to attach that Ďneatí line of plug-welds to filler. See that line of grey shite along the bottom edge there? Oh yes...... I mean come on, Exactly how much intelligence does it take to be able to tell the difference between filler and steel? Obviously more than can be found in the heads of the smeggers down Spon End. And they get paid for this!!!!!!! I actually found that they had been trying to attach that Ďneatí line of plug-welds to filler. See that line of grey shite along the bottom edge there? Oh yes...... I mean come on, Exactly how much intelligence does it take to be able to tell the difference between filler and steel? Obviously more than can be found in the heads of the smeggers down Spon End. And they get paid for this!!!!!!!

Thereís more plug-welds here. Along the top edge (as viewed from this angle) of the cover sill you can clearly see more of those plug-welds. This time theyíre not attached to anything at all. This is the end of the sill that broke off when I folded it down. As it goes the back end would have broken off too had it not been for the patch that had been welded to the inside of the back of the sill. Thatís the Ďtailí you can see in the other image. Also, can you see the white Ďlineí below that? Thatís where more patches had been added to the outside. Considering that these patches werenít actually attached to anything in particular then they were a total waste of time and money. In fact, I havenít covered these in any particular detail because they came off with the cover sill. What was the point of them? Really, was there one at all? I doubt it, beyond getting the car through the

British MOT. Which isnít worth the paper itís printed on. But I digress.

Now bearing in mind that the outer sill skins are actually load bearing member in these cars, unlike the Rover P6, this is quite disturbing. Thatís why it is always imperative that you pay close attention to that little ghost-like swage just below the doors. If thatís missing then you know that important pieces of steel have been messed with. Unless you actually take the car apart youíre not going to know if theyíve been fixed properly or not. A little time on your hands and knees before buying could save you a heck load of time later. And more importantly could save you from dying, should you collide with anything tough. Like a pheasant......

To be Continued

Keil.

|

|

|

|

|

|

|

|

|

|

|