|

Iíve done the coil-over set-up for the convertible, it uses the 74 casings but

with Volkswagen inserts with the original open able struts (they have a shorter body than the

Koni)! and the coil kits for the 88' and up civic, going with the

Volkswagen inserts I

managed to shorten the overall strut housing by about 2 and 1/4 inches and

inserted the Volkswagen insert and then opened up the threaded cap in order to get the

larger diameter Volkswagen shaft thru. So going with this set-up you can slam the car

but keep all the suspension travel and keep

full shock travel. Iíve done the coil-over set-up for the convertible, it uses the 74 casings but

with Volkswagen inserts with the original open able struts (they have a shorter body than the

Koni)! and the coil kits for the 88' and up civic, going with the

Volkswagen inserts I

managed to shorten the overall strut housing by about 2 and 1/4 inches and

inserted the Volkswagen insert and then opened up the threaded cap in order to get the

larger diameter Volkswagen shaft thru. So going with this set-up you can slam the car

but keep all the suspension travel and keep

full shock travel.

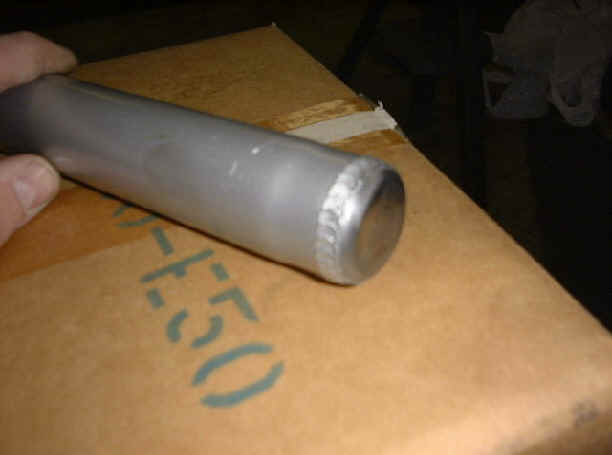

The inserts are designed for the first generation Volkswagen Rabbit (75'-84) they are made

by KYB, they are the only ones I found that fit into the Civic housing.

The first picture shows my buddies Tein coil-over kit

(on the left) it will fit in the front for the Civic!

The first picture shows my buddies Tein coil-over kit

(on the left) it will fit in the front for the Civic!

Here's the picture of the rear with the coil-over all the way up and then all the way down.

There is more threaded area on the Volkswagen strut, but when we did the rears we actually

machined down the shaft to gain more clearance, so that we could go with the

factory rear strut bushings, we just made a new sleeve that we pressed into the

original bushings, With the Volkswagen inserts being 3" shorter than the rear

housing we just cut the excess out of the housing (only 2" and then added a

spacer to make up the difference in height) and then Tig welded it back

together. We then took the original strut cap and opened the hole to accept the Volkswagen insert. The front is done the same way except on the bottom of the

Volkswagen inset it has a spacer that's Tig welded on, We removed it in order to have the right

clearance. Here's the picture of the rear with the coil-over all the way up and then all the way down.

There is more threaded area on the Volkswagen strut, but when we did the rears we actually

machined down the shaft to gain more clearance, so that we could go with the

factory rear strut bushings, we just made a new sleeve that we pressed into the

original bushings, With the Volkswagen inserts being 3" shorter than the rear

housing we just cut the excess out of the housing (only 2" and then added a

spacer to make up the difference in height) and then Tig welded it back

together. We then took the original strut cap and opened the hole to accept the Volkswagen insert. The front is done the same way except on the bottom of the

Volkswagen inset it has a spacer that's Tig welded on, We removed it in order to have the right

clearance.

The shaft is longer than the OEM one. For street applications, it's not very often

you are going to get enough travel to unseat the spring. I also machined out the top strut plate and inserted a Mono-ball bearing, this

should stop the problem if it were to ever unseat, or you can go with a helper

spring in order to take up the slack. My buddy's set-up is for a 93 Civic

hatchback. The shaft is longer than the OEM one. For street applications, it's not very often

you are going to get enough travel to unseat the spring. I also machined out the top strut plate and inserted a Mono-ball bearing, this

should stop the problem if it were to ever unseat, or you can go with a helper

spring in order to take up the slack. My buddy's set-up is for a 93 Civic

hatchback.

When we did the rears we actually machined down the shaft to gain more

clearance, so that we could go with the factory rear strut bushings, we

just made a new sleeve that we pressed into the original bushings, With

the Volkswagen inserts being 3" shorter than the rear housing we just cut

the excess out of the housing (only 2" and then added a spacer to

make up the difference in height) and then tig welded it back together.

We then took the original strut cap and opened the hole to accept the

Volkswagen insert. The front is done the same way except on the bottom of the Volkswagen

inset it has a spacer that's tig welded on. We removed in order to have

the right clearance. When we did the rears we actually machined down the shaft to gain more

clearance, so that we could go with the factory rear strut bushings, we

just made a new sleeve that we pressed into the original bushings, With

the Volkswagen inserts being 3" shorter than the rear housing we just cut

the excess out of the housing (only 2" and then added a spacer to

make up the difference in height) and then tig welded it back together.

We then took the original strut cap and opened the hole to accept the

Volkswagen insert. The front is done the same way except on the bottom of the Volkswagen

inset it has a spacer that's tig welded on. We removed in order to have

the right clearance.

Justin

|